Case study

Rain Erosion Tester to LM Wind Power

The guarantee of repeatability was a determining factor when LM Wind Power chose R&D Test Systems' system for their future in-house tests.

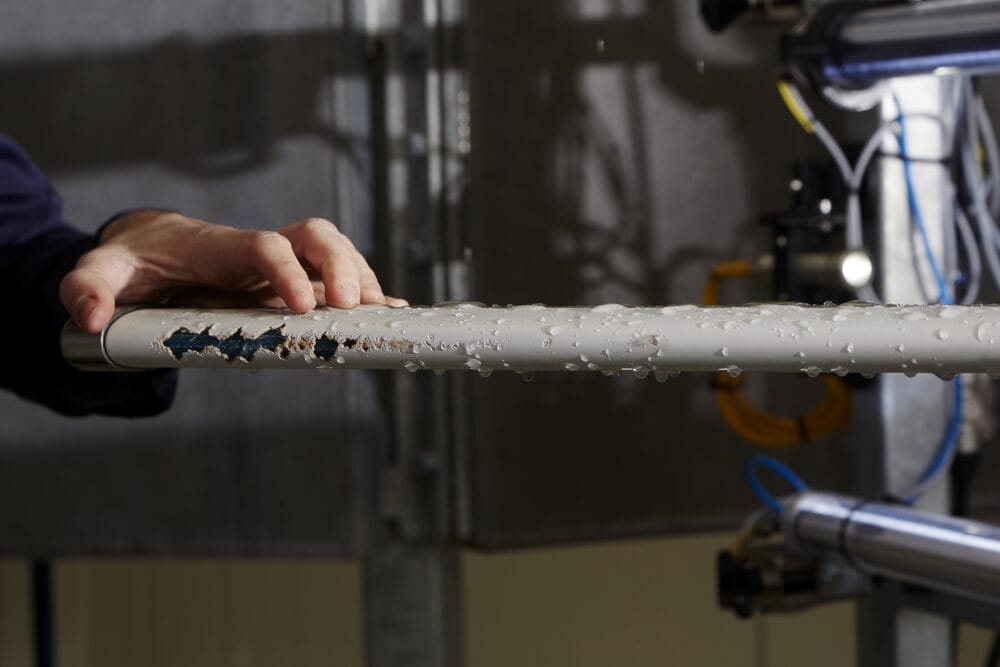

Erosion at the tips of wind turbine rotor blades can lead to the surfaces of the rotor blades peeling off, which will create an aerodynamic loss and thus a potentially larger power loss. Therefore, it is crucial for wind turbine manufacturers that they have the best opportunities to test the durability of various types of rotor blade coatings and that the tests are as realistic as possible.

The documented repeatability in R&D Test Systems' solution was a determining factor in our decision to buy their Rain Erosion Tester.

Intensive course of development

Throughout the last three years, R&D Test Systems has been working intensively on the development of a Rain Erosion Tester, and the result is based on more than 10,000 hours of development. The development has taken place in close collaboration with multiple customers. R&D Test Systems is also collaborating with DTU Wind Energy on a project funded by EUDP, which develops the technology further within certain fields.

“R&D Test Systems' broad experience within the development of test systems combined with the qualities of the developed Rain Erosion Tester have been the determining factors in our choice of R&D Test Systems as a collaborator,” Laurids Andersen, test engineer at LM Wind Power, says. “We have had some very nice and constructive discussions throughout the entire process, and our collaboration will continue as the solution will be developed further with the results of the EUDP project.”

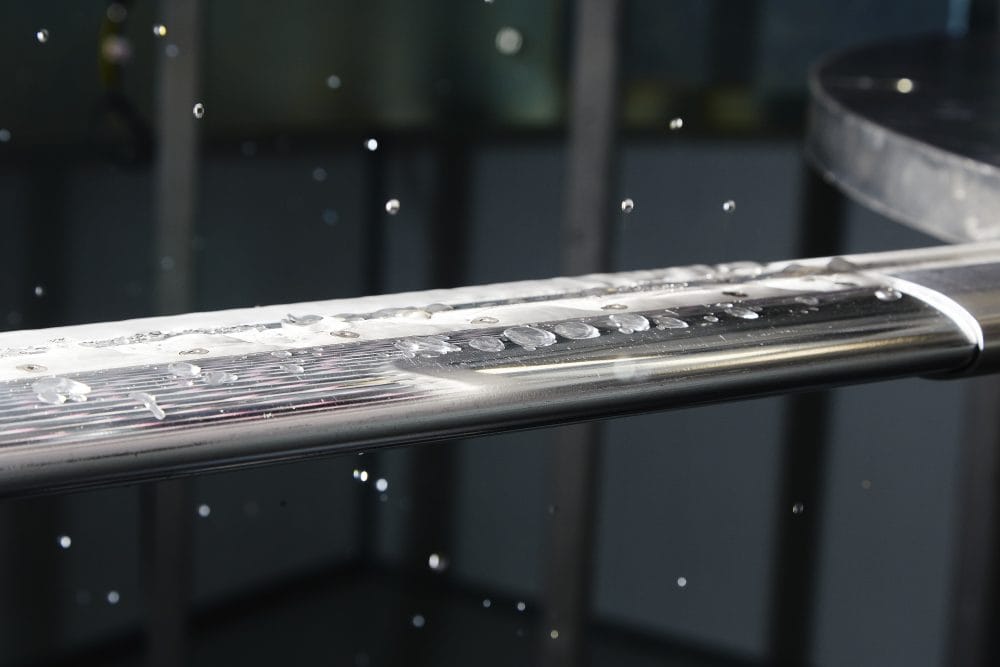

“Test of rain erosion is very complicated and the surface is very difficult to test because of the speed. The tip speed is approximately 180 m/sec.,” Mads Erik Mathiesen says, mechanical engineer at R&D Test Systems. “Therefore the development process requires many tests in practice. We cannot calculate everything purely theoretically – but it does require a strong theoretical base to reach the right solution.”

Documented repeatability

“One if the big challenges of the development process has been to create an aerodynamic area around the machine and especially the rotor blades in the machine,” Mads Erik Mathiesen says. “One of the challenges has been to make the drops fall straight downwards and hit the test subject without the drops curving or being affected by another turbulence in the machine. We have solved that issue and today we have a very stable machine.”

“The documented repeatability in R&D Test Systems' solution was a determining factor in our decision to buy their Rain Erosion Tester,” Laurids Andersen says. “We need to be able to trust the results of the regular tests in our development work and to know that it is the test subjects and not the machine which create the differences from one test to another. At the same time, this solution offers more measurable parameters than we have today, and knowledge is stored in-house. In general, we expect better tests, a larger collection of knowledge, and thereby a better course of development.”

“With our solution, the industry has gained a more reliable test method in a complex field. This can be significant for the development of new wind turbine rotor blades,” Peter Kattai Ulrikkeholm says, Business Unit Director at R&D Test Systems. “With our Rain Erosion Tester, we are meeting a demand in the industry. The first solutions have already been sold and delivered to significant players in the wind industry such.”

Adjustable test parameters

How can we help you?

For more information on our Rain Erosion Tester, please contact us.