Test Systems

DTU buys rain erosion tester to improve research and development

DTU buys rain erosion tester to improve research and development

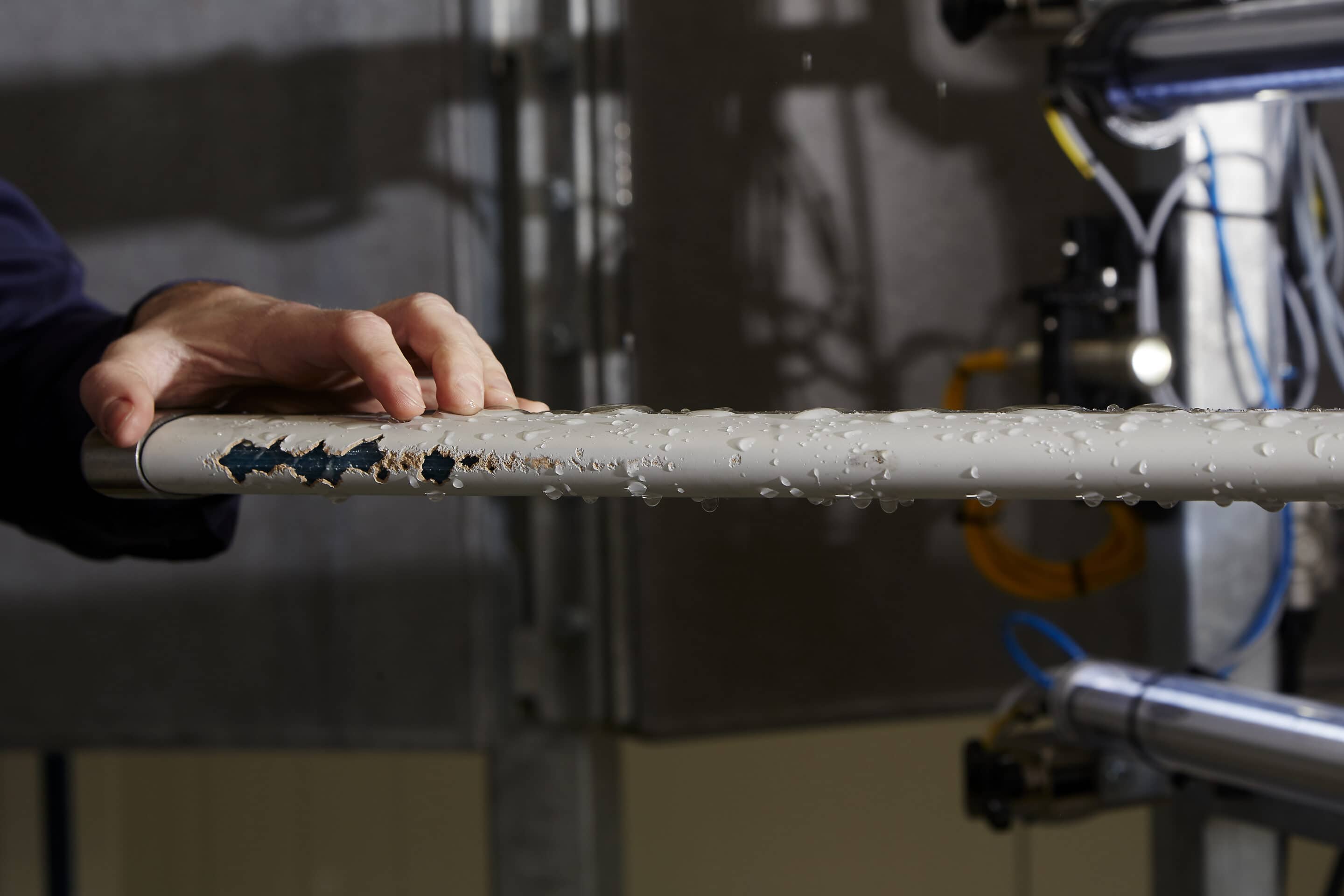

It is a well-known and significant problem that wind turbine blades become worn out due to rain, especially along the tip section of the blade. When the blade coating is damaged by rain, the efficiency of the wind turbine is impaired and expensive repairs are necessary.

Rain erosion is, therefore, a frequently discussed challenge which both wind turbine manufacturers and wind farm owners are keen to address.

DTU is the world’s leading research institute within the field of rain erosion on wind turbines and has participated in several projects over the years, including projects with the supplier of its new testing machine, R&D Test Systems. Therefore, it is particularly exciting that DTU now has its own Rain Erosion Tester, which will be used across several different research projects.

What is a Rain Erosion Tester?

A rain erosion tester (RET) is a testing machine based on a three-bladed helicopter principle, where a test specimen is rotated at high speed and exposed to raindrops. The RET provides the right set-up for the most realistic test conditions in a controlled environment, where it is possible to simulate different types of rain and test accelerated lifetime for leading edge protection.

New features pave the way for new testing methods

The RET which DTU has purchased will be the most advanced on the market and will be able to emulate rain with three times the intensity because the rain field can be opened up to 1,800 needles instead of the standard 600 needles. In addition to increased rain density, DTU has also chosen to incorporate a heat pump to heat the ventilation air, which, in addition to drastically reducing energy consumption, also provides increased possibilities for controlling the temperature.

“It is a well-known issue that a test acceleration at increased speed can cause erosion phenomena that do not replicate reality. With three times as many droplets, DTU will examine the possibilities for accelerating the erosion tests without compromising the results,” explains Niels Pedersen, key account manager at R&D Test Systems.

“Time is money, so our customers are always interested in shortening a test period if it can be done without impairing the results, so we’re very much looking forward to developing a machine where the tests can be accelerated to a greater extent by increasing the rain density,” says Niels Pedersen.

Another feature of DTU’s testing machine is a new heat pump integration in the ventilation system, which, in addition to enhancing overall efficiency, also allows DTU to control the temperature of the ventilation air better. This provides better possibilities for investigating the influence of different air temperatures on rain erosion tests.

“The testing machine is improving our possibilities for researching and testing new solutions, and we’re very excited at the prospect of taking it into use. It has been a constructive process collaborating with R&D Test Systems on implementing the new features in the machine,” says Ignacio Marti, head of division at DTU Wind and Energy Systems.

The new testing machine will be installed at DTU Risø Campus, where a new purpose-built test facility will soon see the light of day. “For the first time, we are establishing a custom-designed test chamber so that DTU has exactly the dimensions it wants. DTU wanted a larger test chamber and more space for the operators, who can also enjoy one of the best views in Denmark overlooking Roskilde Fjord,” says Niels Pedersen in conclusion.