Test Systems

R&D Test Systems secures largest order to China

R&D Test Systems secures largest order to China

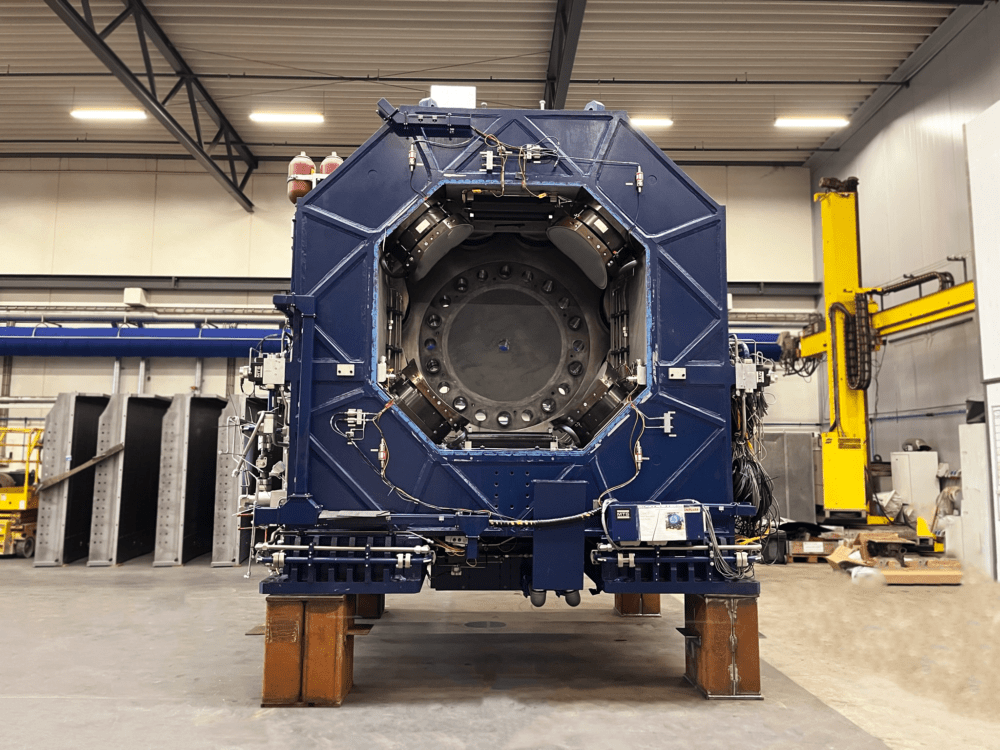

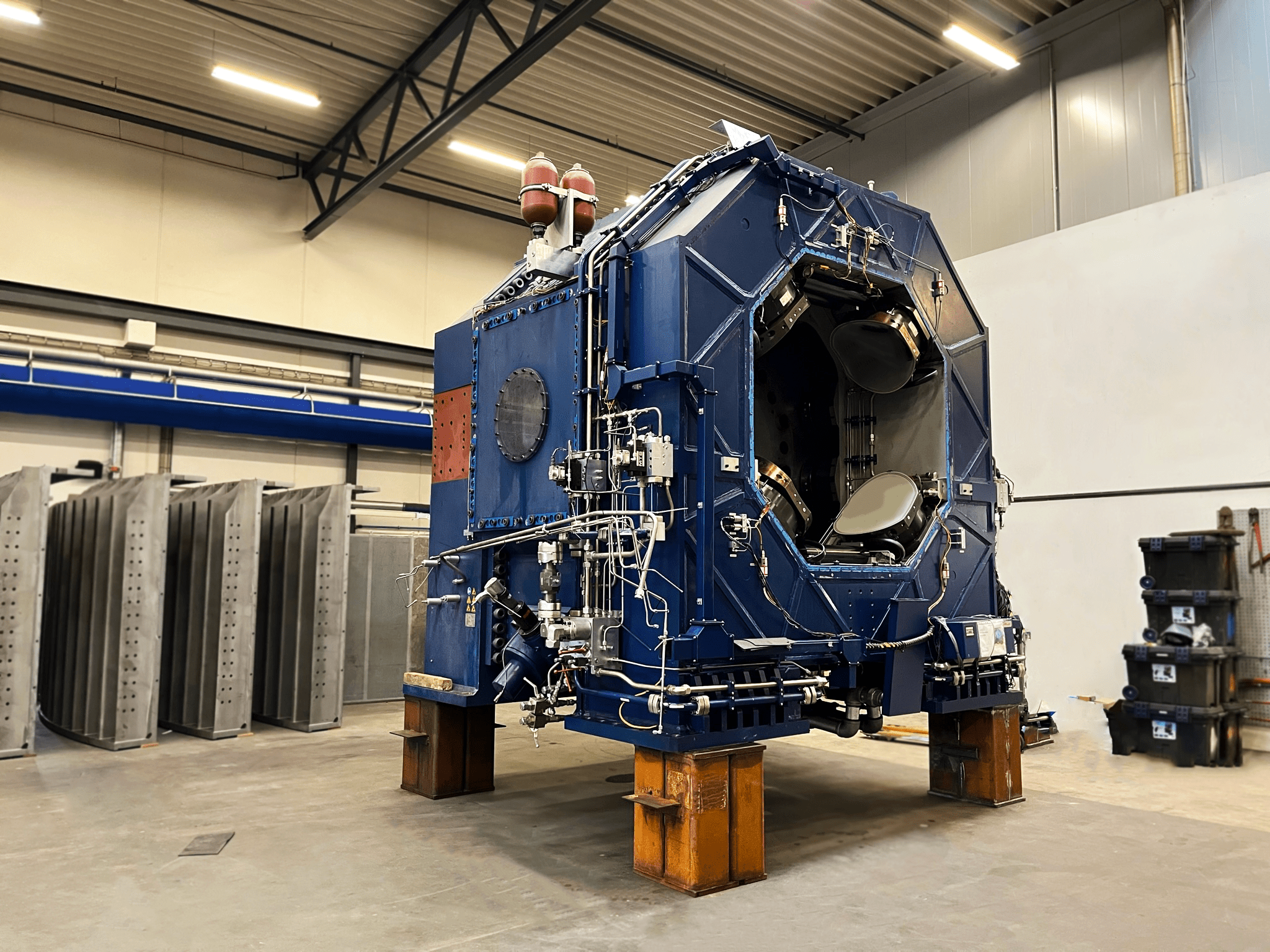

The new test bench is a large hydro-static test load unit and will be R&D Test Systems’ largest project for a Chinese customer to date. The test bench will be installed in a new-built bearing test center at Zhejiang Tianma Bearing Group (TMB), who is one of the largest bearing manufacturers in China and a global supplier of bearings to the leading wind turbine OEMs.

“It is a milestone project in China, and the cooperation with TMB has been good and very efficient, enabling us to deliver the test bench with a short delivery time,” explains Kasper Willatzen, Sales Manager at R&D Test Systems.

It is a milestone project in China, and the cooperation with TMB has been good and very efficient, enabling us to deliver the test bench with a short delivery time.