Test Systems

Flender has commissioned two large test systems for wind turbine gearboxes and drivetrains

Flender has commissioned two large test systems for wind turbine gearboxes and drivetrains

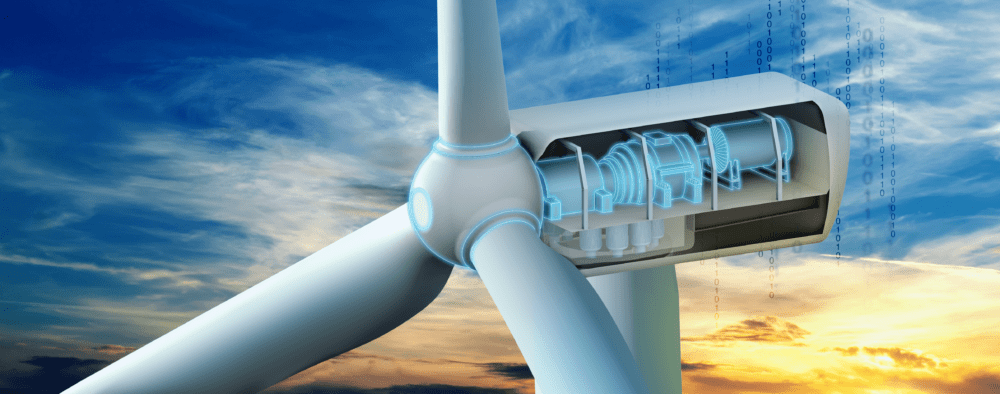

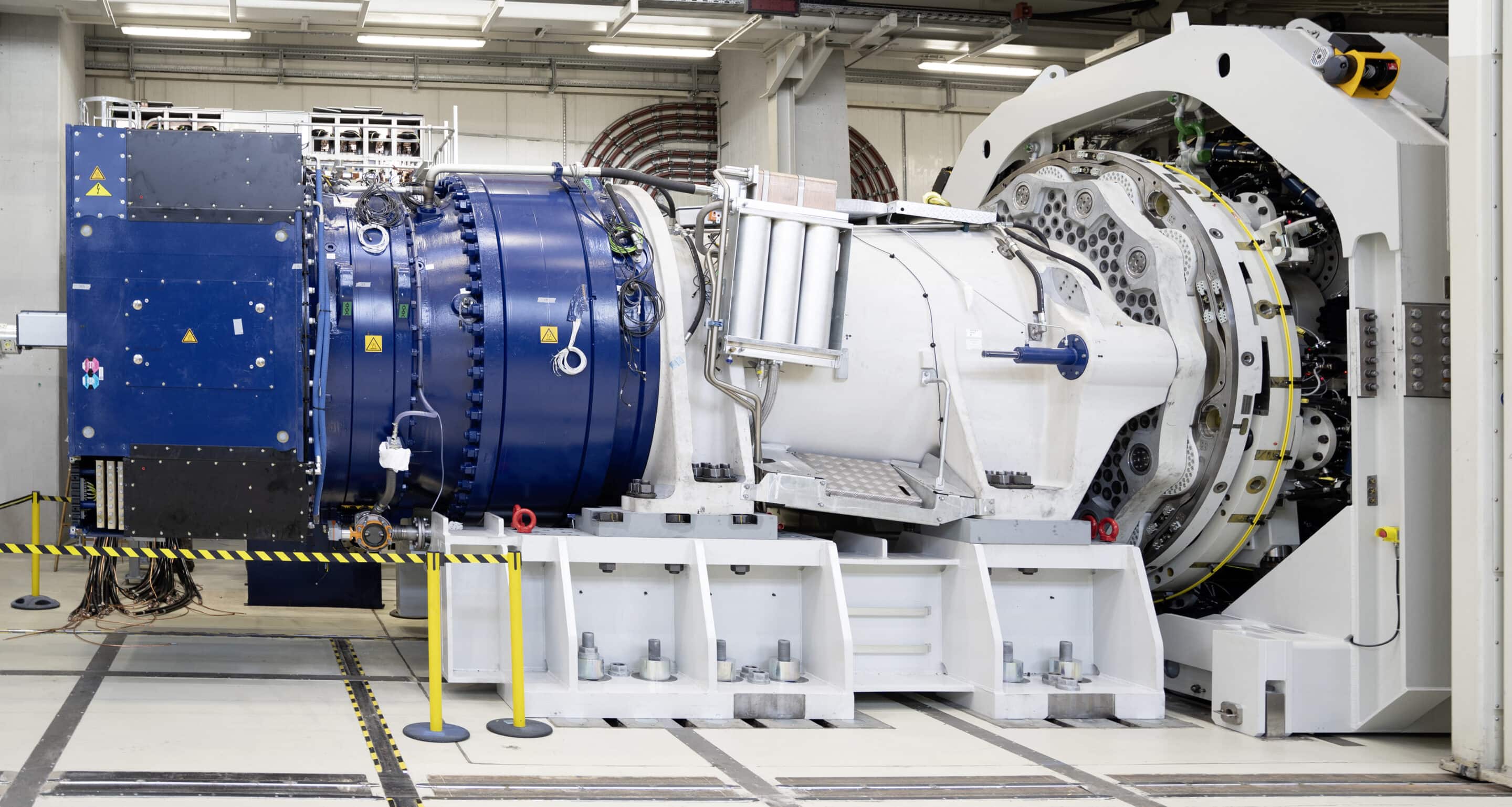

Flender, one of the leading suppliers of gear solutions and electrical drive systems for wind turbines, has integrated a new production line in two of their factories at which they are manufacturing and assembling complete drivetrains for their customers.

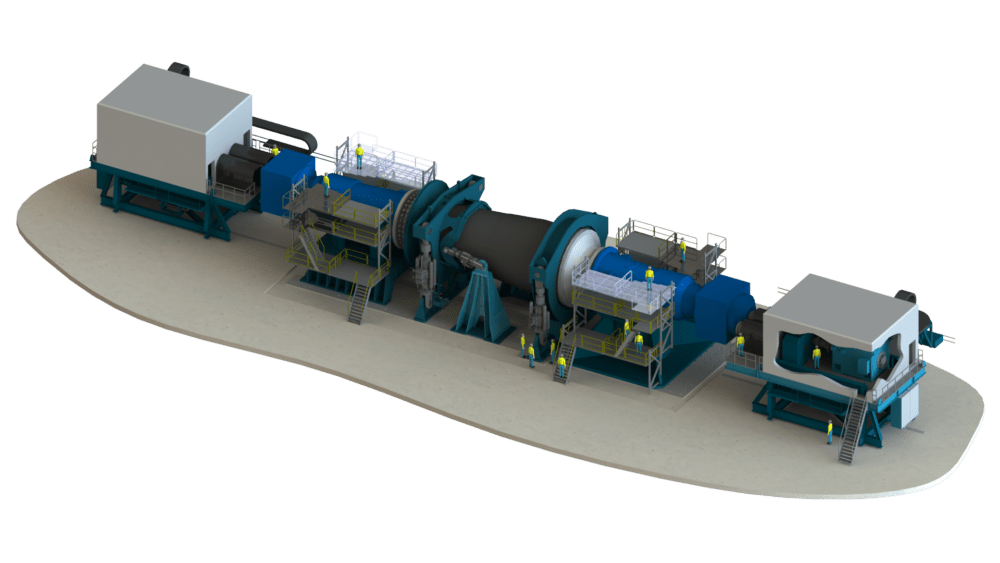

The new production line requires new testing capabilities to be able to validate the quality and performance of the products. More specifically, Flender wanted a test system that can perform End-Of-Line (EOL) testing of all drivetrains prior to shipment. The new gearboxes are produced at two of Flender’s factories: Voerde in Germany and Tianjin in China. Hence, Flender needed two of the same EOL test benches.

“End-Of-Line testing, which is the final check before a product leaves a factory, is a crucial step in a production process. At R&D Test Systems, we develop specialized test systems in line with our customer's requirements. We have a lot of experience and in-house competencies, which means that we, in this case, were an ideal partner for Flender,” says Lars Brunsgaard Poulsen, Project Director at R&D Test Systems.

Back-to-back principle

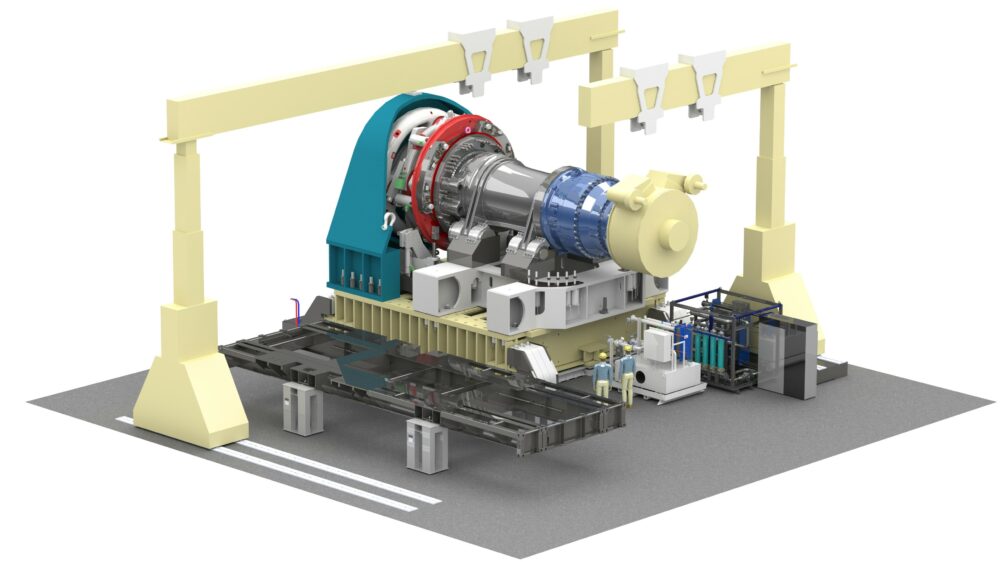

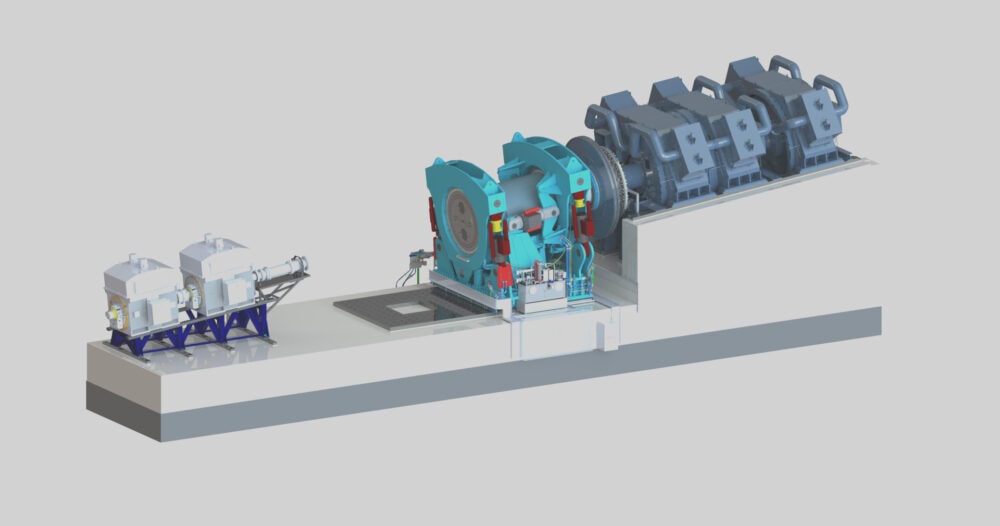

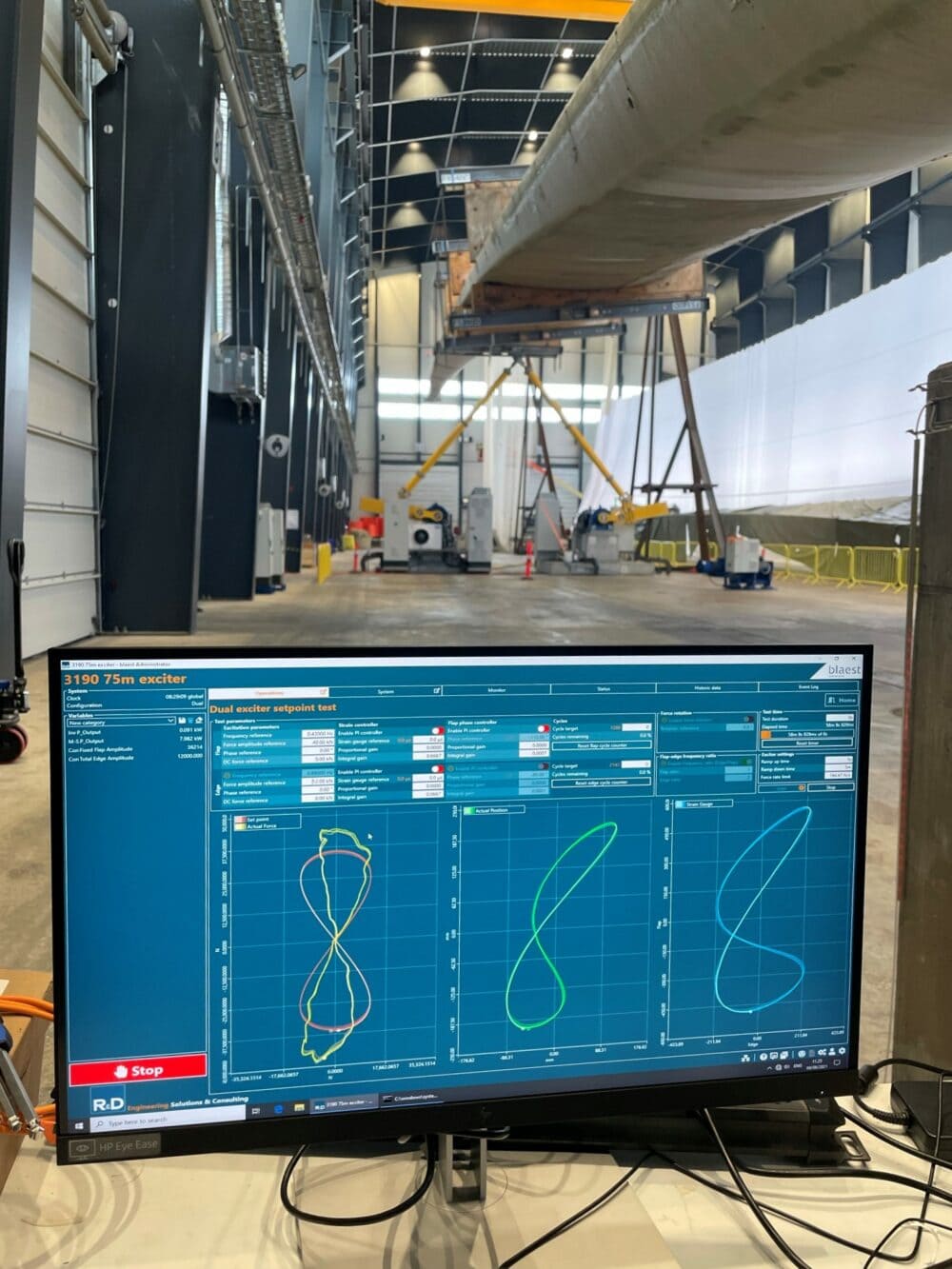

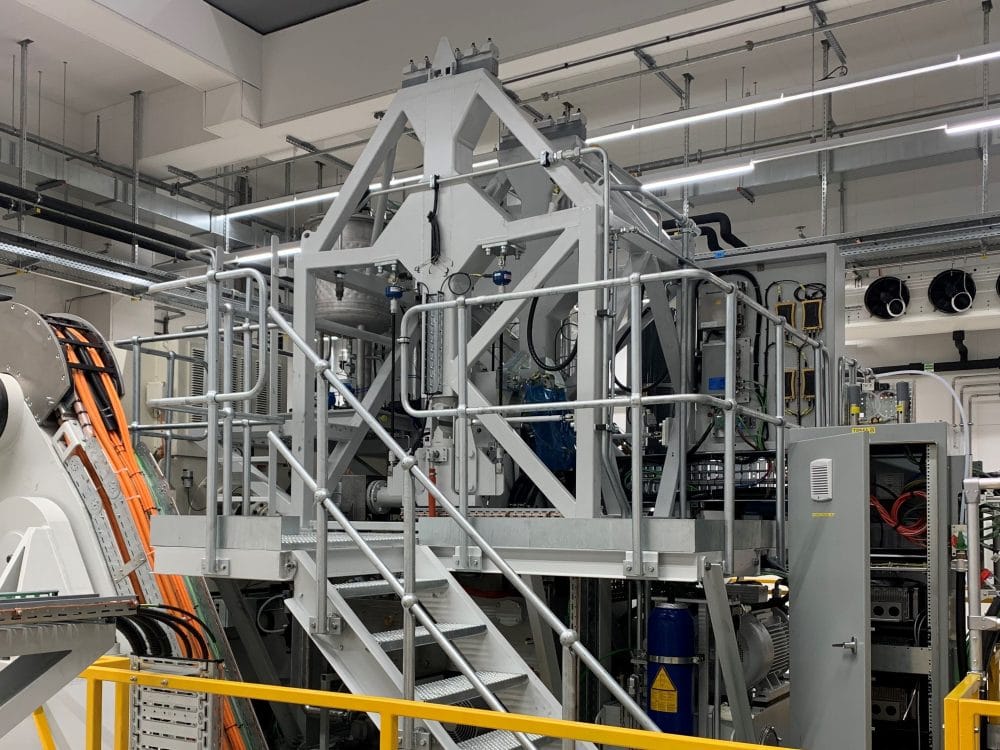

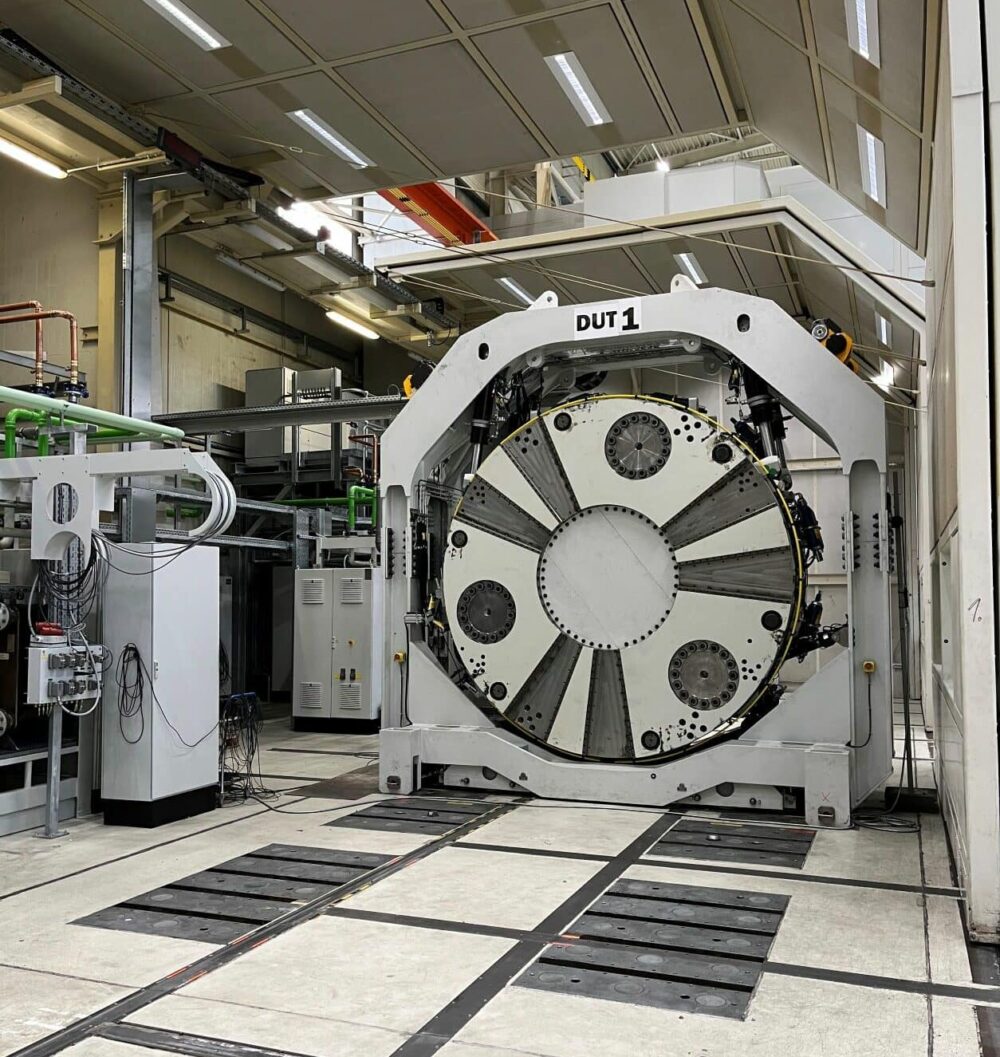

The purpose of the test system is to test turbine drivetrains. The new 10 MW EOL test benches are based on the electrical back-to-back principle, which means that Flender can set up two full drive trains opposite each other and test them simultaneously. With this setup, it is possible on each factory to fully test 4 drivetrains in approx. 26 hours, as each test circle takes around 8 hours and the exchange of two drivetrains takes around 5 hours. The exchange time also covers removal of electrical power cables, oil lubrication hoses, cooling hoses, cables for DAQ and control system as well as all mechanical connections.

The back-to-back principle is well known in the industry for gearboxes but has in this project with a strong alignment of Flender and R&D Test Systems been applied to drivetrains as well to ensure high production output and regeneration of the consumed power. When the consumed energy is regenerated, only the losses are to be fed into the system, making operation of the test benches more sustainable. Furthermore, these systems can test complete medium-speed drivetrains, consisting of the main bearing unit with main shaft, gearbox, and generators. Another aspect of the new test benches is that costumer data acquisition and all instrumentation on the drivetrain is included in the test setup, thus all sensors and actuators are fully tested. This secures a high level of quality insurance before the drivetrain leaves the factory for onsite installation.

Managing supply chain issues during Covid-19

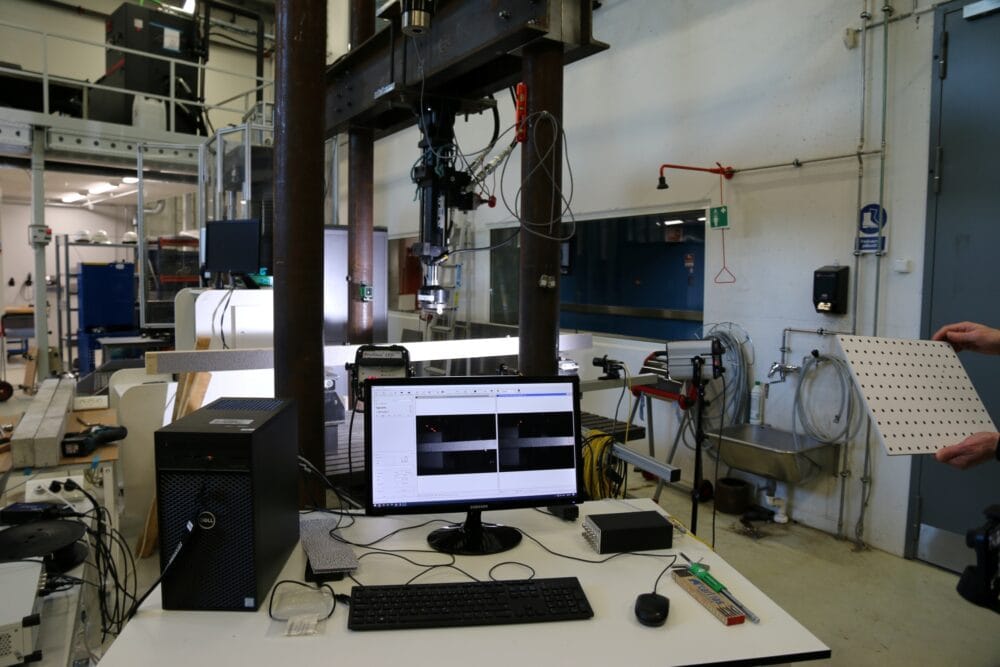

During 2019, R&D Test Systems and Flender started the collaboration and development of the two test benches. However, just as the project was about to start the world was faced with Covid-19. Like many others, the project experienced supply chain challenges and restrictions forcing R&D Test Systems to develop new techniques for remote installation and commissioning.

In Germany, the test bench was installed with very restricted access to the facility and in China the test bench was supervised and commissioned from R&D’s headquarter in Denmark only supported on-site by two Chinese colleagues. This was only possible with a very close cooperation and coordination between Flender and R&D and because of R&D Test Systems' digitalization and simulation capabilities, which enabled them to support the commissioning of the test system remotely.

Testing complete drivetrains

From the start, the project objective has been to develop a test system that can perform functional test and rotational load test of full drivetrains in one set-up. With the two new test benches installed in Germany and China, Flender can test complete drivetrains and validate the performance and quality. A high level of automation ensures that Flender can fully test almost 4 drivetrains per day on each of the test systems, leading to increased production output. As a result of the new EOL test capabilities, Flender can better meet the demand from its customers.

“We want to perform precise and efficient tests of our new product line, making it necessary to have an EOL test bench designed specifically to our needs and requirements. As the test system integrates the entire drivetrain, we can execute EOL gearbox load testing along with the functional tests and maintain a high production output,” says Jan-Dirk Peters, Head of Sales Winergy Gearboxes.

The project started in 2020 and the final handover from R&D Test Systems to Flender has just been done.