Test Systems

Highly Accelerated Life-cycle (HALT) Test

Large-scale and sustainable solutions

Highly Accelerated Life-cycle (HALT) Test

Large-scale and sustainable solutions

HALT testing: Design verification and Life-time validation

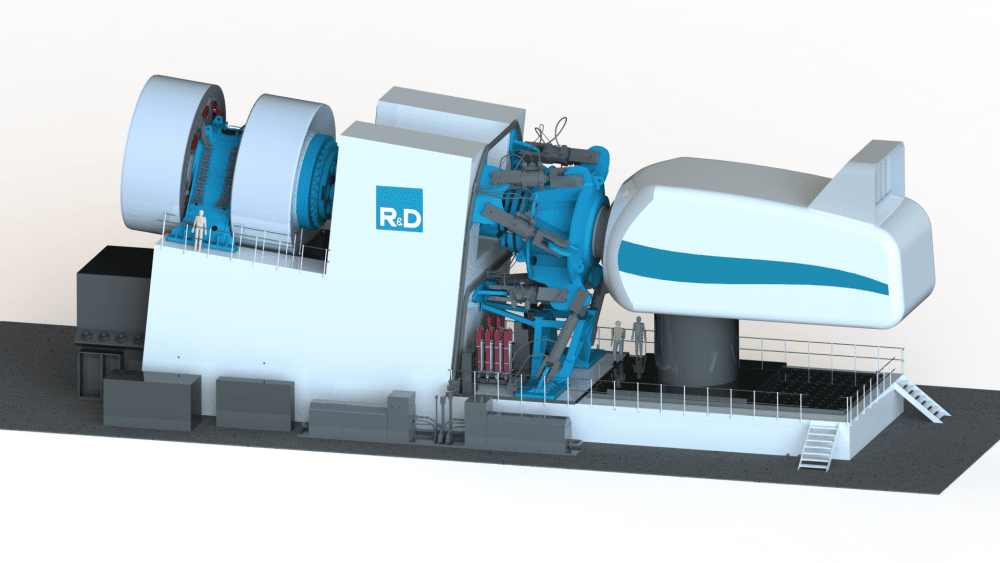

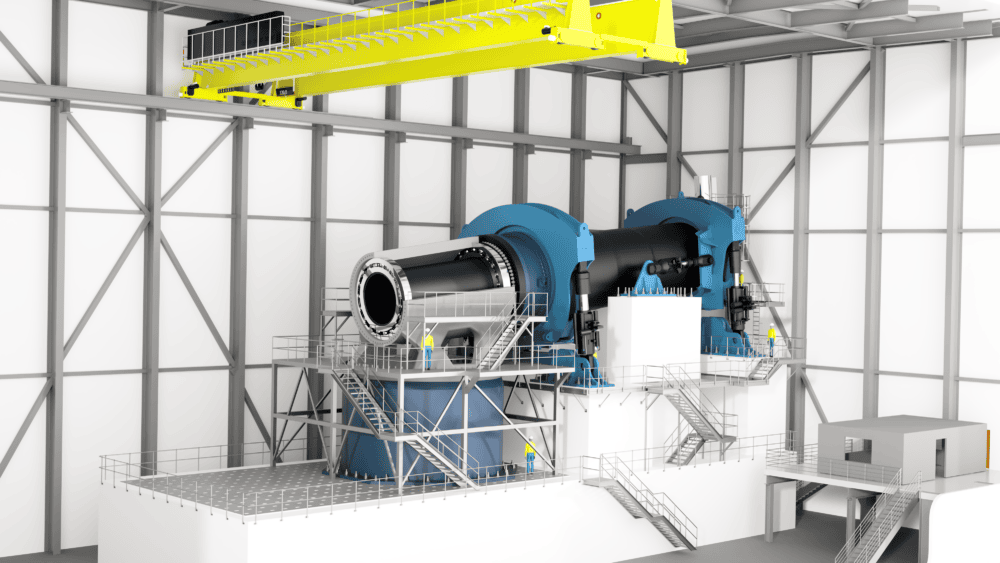

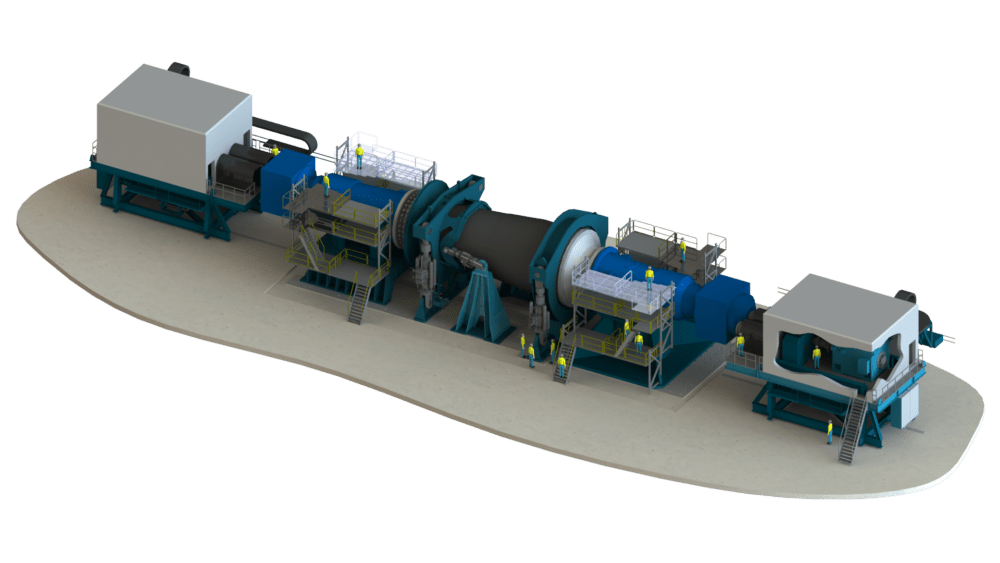

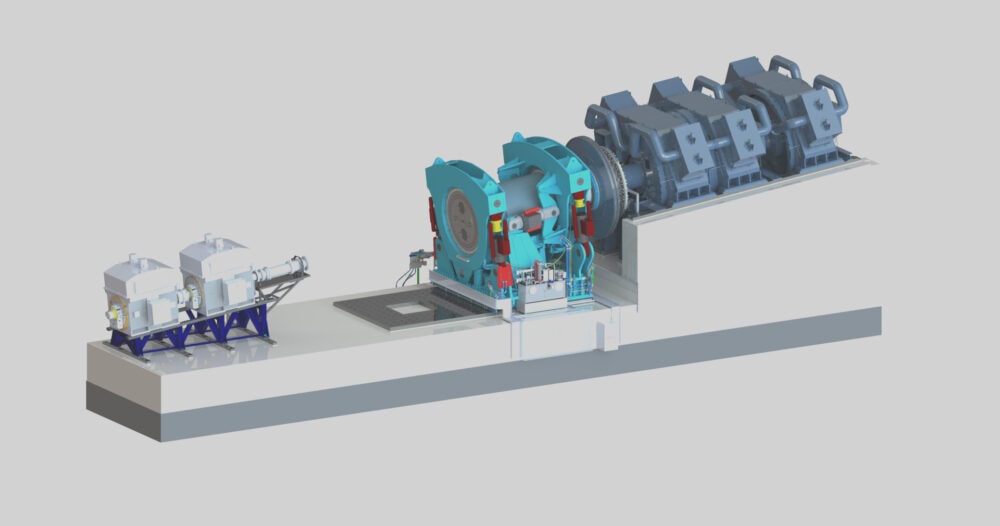

The HALT test benches enable wind turbine manufacturers to test the function and life-cycle of different wind turbines faster and better than ever before at Lindø Offshore Renewables Center (LORC).

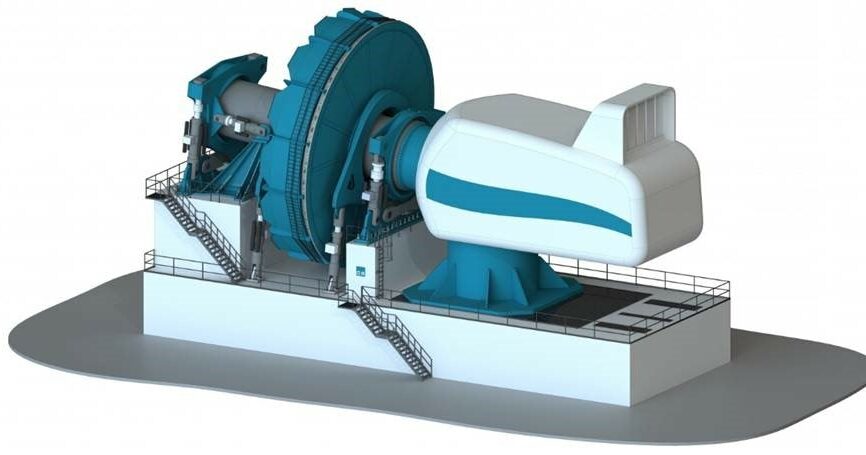

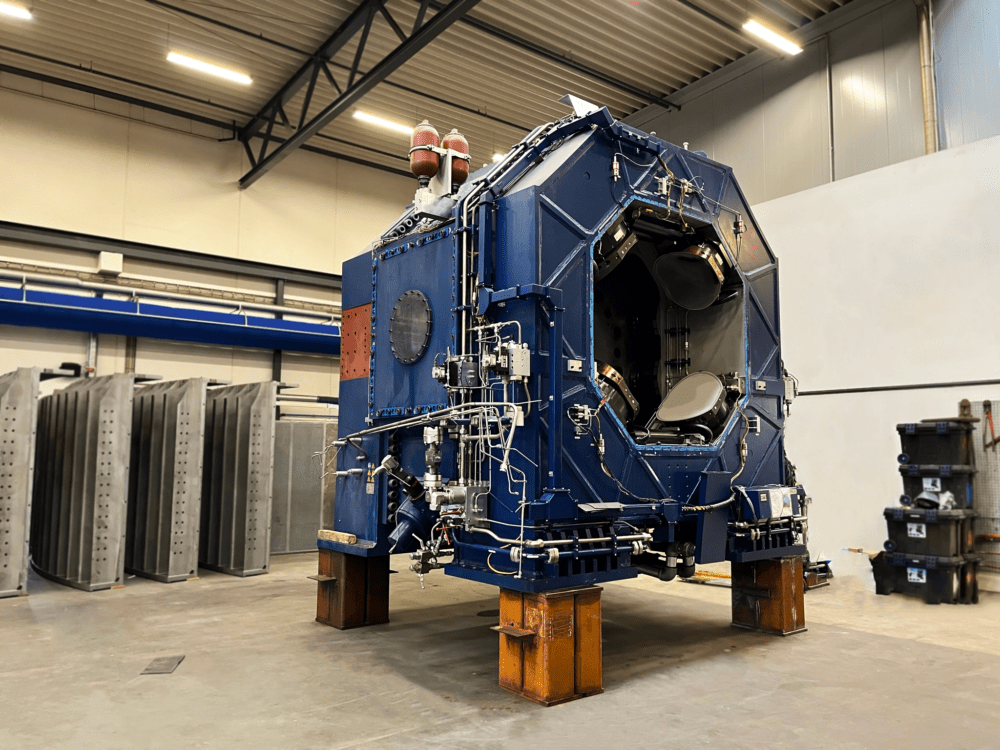

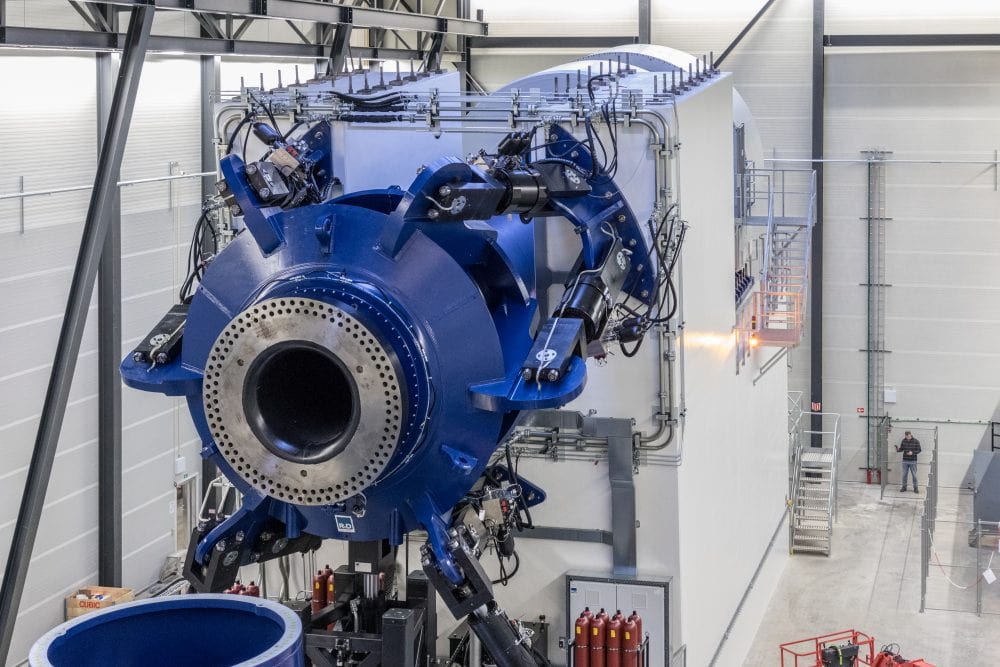

The HALT test bench and HALT XL test bench test the next generation of prototypes of the world’s largest offshore wind turbines to make sure that the enormous energy giants can withstand the scenarios out on the ocean. This requires a test bench out of the ordinary.

Both test benches are used for design verification and Highly Accelerated Life-time Testing (HALT) of nacelles as well as drive-train components such as gearboxes and main bearings.

R&D Test Systems has developed test benches that will expose the prototype to 20 years of the elements in just 6-8 months.

25 MW Test Facility at LORC

Previously, R&D Test Systems has developed and build test benches for LORC, including some of the largest in the world. Therefore, it has been the natural choice for us to seek competences, know-how, and especially the innovative approach, which R&D Test Systems can provide.

The project phase of your next test system

To develop large-scale industrial test systems such as the HALT test bench and HALT XL test bench, we follow the below project model. Due to our high expertise and knowledge, we understand our customers' needs and ensure their competitiveness.

R&D Test Systems

Large-scale and Sustainable Solutions

R&D Test Systems has a workforce of engineering experts who have acquired specialized competencies through years of developing complex, large-scale dynamic test systems.

Our in-house specialists enable us to address the system and provide the deliverables required for the complete scope of the test system, including feasibility study, design, manufacturing, installation, and commissioning.

How can we help you?