Bolt-Check

Vestas achieves efficiency and accuracy of its bolted joints

Vestas achieves efficiency and accuracy of its bolted joints

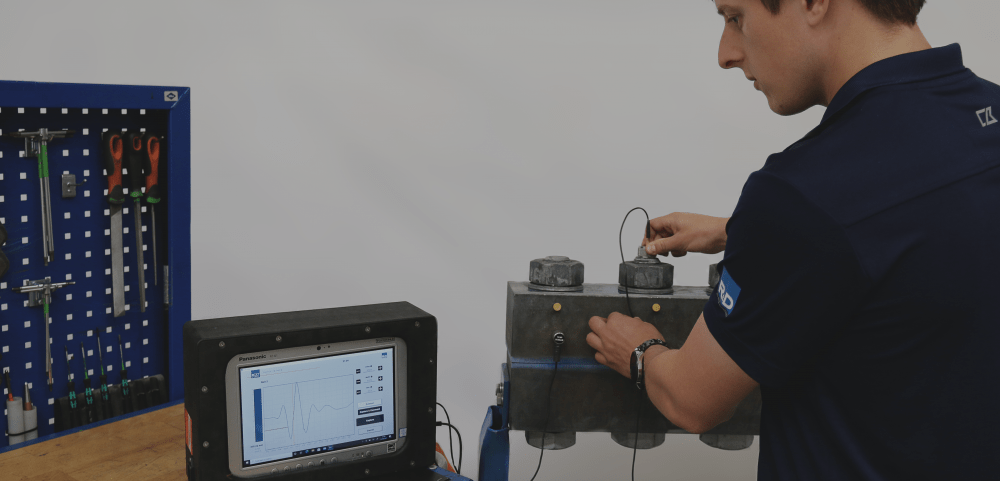

Bolt-Check is used to verify the bolt pre-tension of wind turbine blade studs. With this measurement system, Vestas has been able to optimize its construction time and ensure the accuracy of its calculations and assumptions.

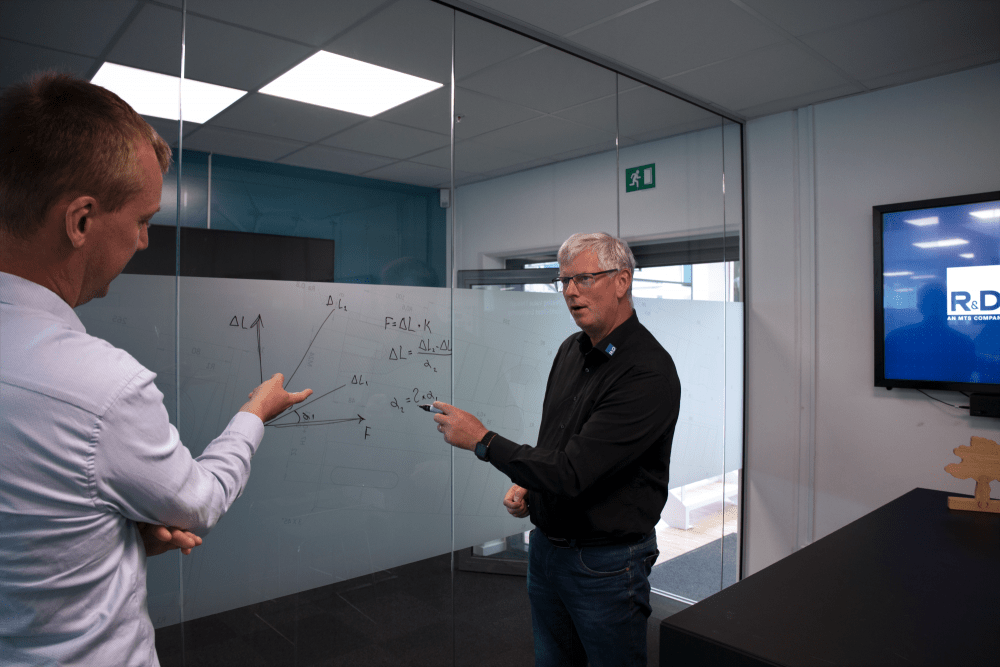

“By using Bolt-Check as a documentation tool, we are able to investigate how the reality and calculations of the installation process align. R&D Test Systems can provide a solution that goes beyond theoretical calculations by using the Bolt-Check tool to provide actual data from the construction site,” explains Peter Bækhøj Schandel, Blade Bearing Engineer at Vestas.

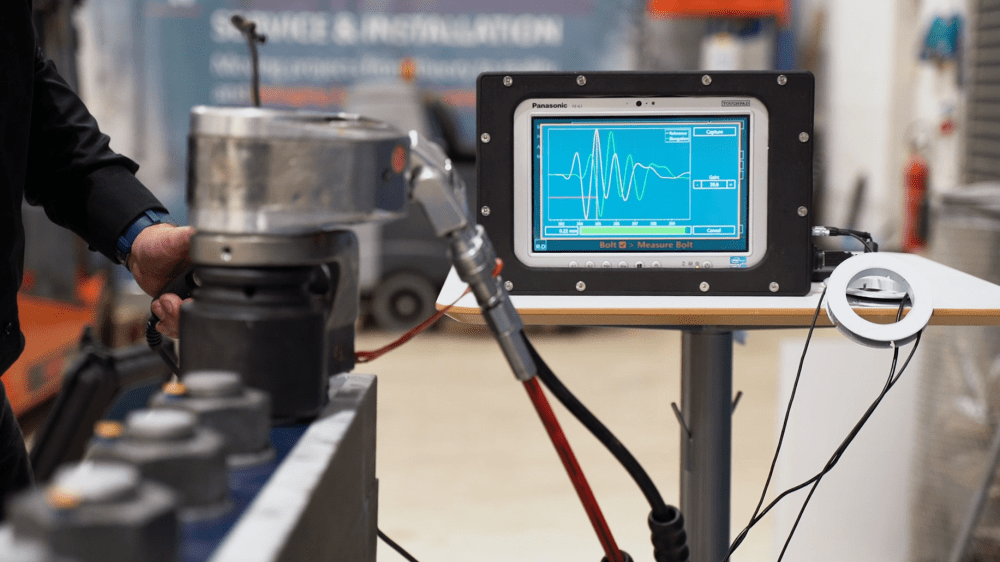

The Bolt-Check tool uses ultrasonic technology to determine the clamping force of the joints, ensuring that the bolted joints within the wind turbine are correctly tightened. This real-time data allows operators to verify the bolt pre-tension of wind turbine blade studs quickly and easily, which is critical for maximizing the operating time of the turbine and, at the same time, minimizing failure.

“Vestas requested a measuring campaign at a turbine in Wöhrden, Germany. As a part of the optimization of the construction time, Vestas wanted to investigate alternative tightening methods, and how much clamping force remains just after tightening and approx. one week after tightening,” says Jens Vestergaard Nybo, Key Account Manager at R&D Test Systems.

R&D Test Systems' Bolt-Check tool is helpful in enhancing Vestas' efficiency and accuracy in wind turbine construction. By utilizing ultrasonic technology for data-driven calibration and optimization, Vestas is able to maximize the bolt pre-tension accuracy and ensure the proper functioning and durability of their wind turbines.

Enhancing Vestas' efficiency and accuracy in wind turbine construction

R&D Test Systems' Bolt-Check tool is helpful in enhancing Vestas' efficiency and accuracy in wind turbine construction. By utilizing ultrasonic technology for data-driven calibration and optimization, Vestas is able to maximize the bolt pre-tension accuracy and ensure the proper functioning and durability of their wind turbines.

R&D Test Systems can provide a solution that goes beyond theoretical calculations by using the Bolt-Check tool to provide actual data from the construction site.