Test Systems

Wind turbine blade testing

Wind turbine blade testing

Wind turbine blade test systems

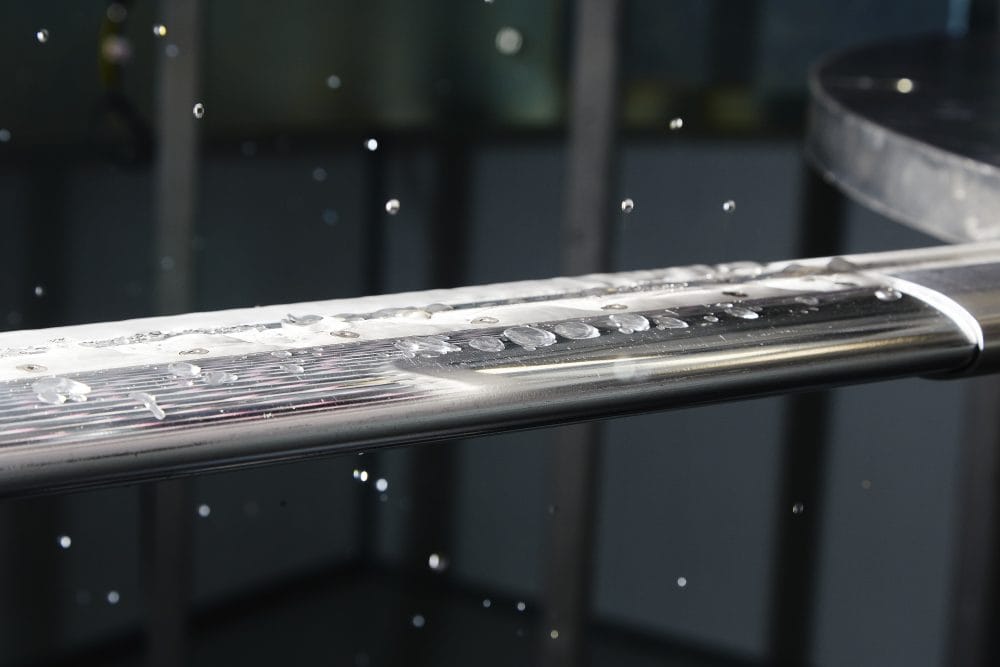

Rotor blades are subjected to both aerodynamic loads and inertial loads, which cause them to bend and twist in different directions. As blade design continues to increase in dimension and proportion, the requirements of your test equipment increase as well.

With our unique experience within test systems for the wind industry, you get advanced test solutions for your rotor blade; from a standard test system to a tailor-made turnkey test system.

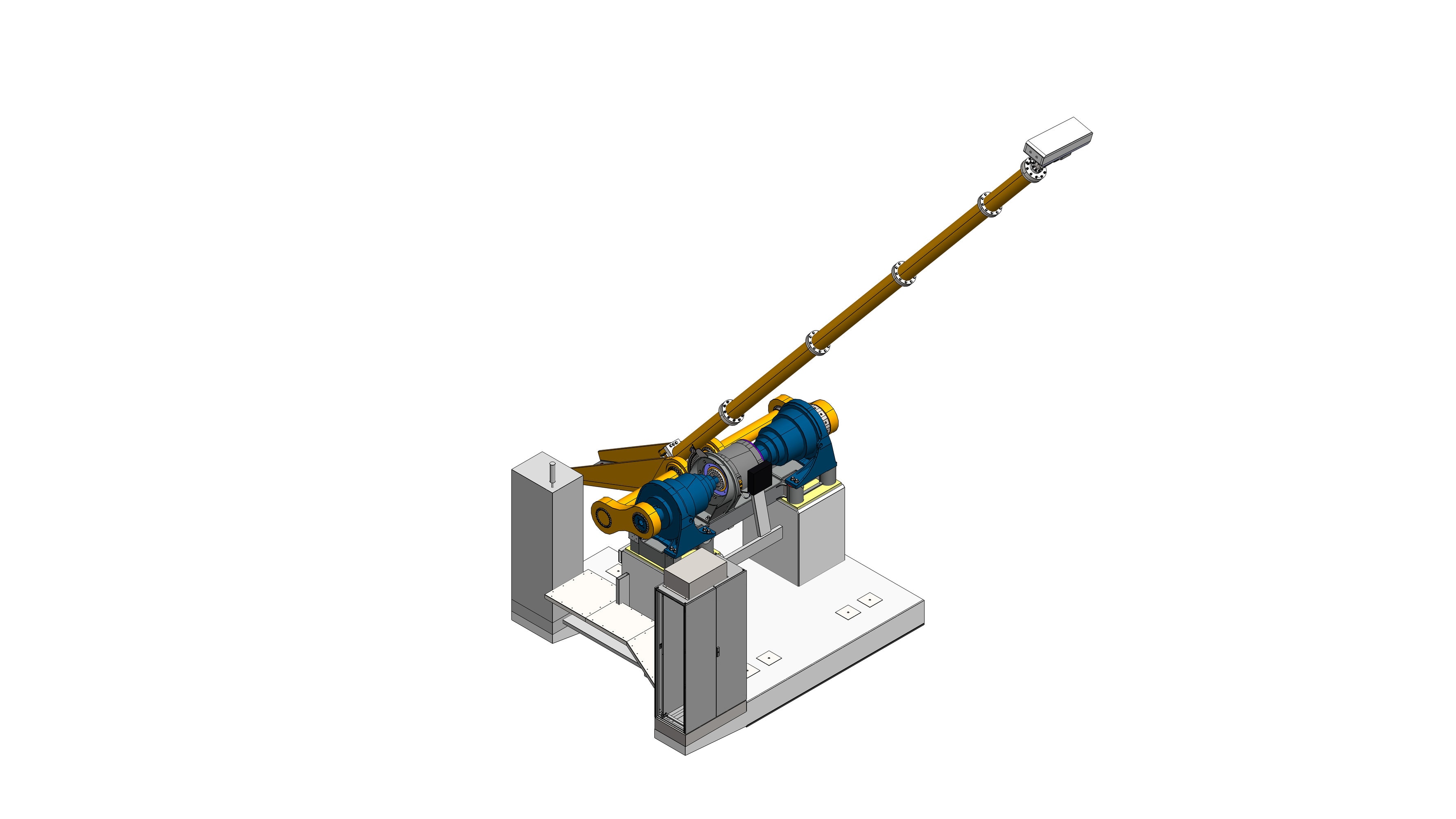

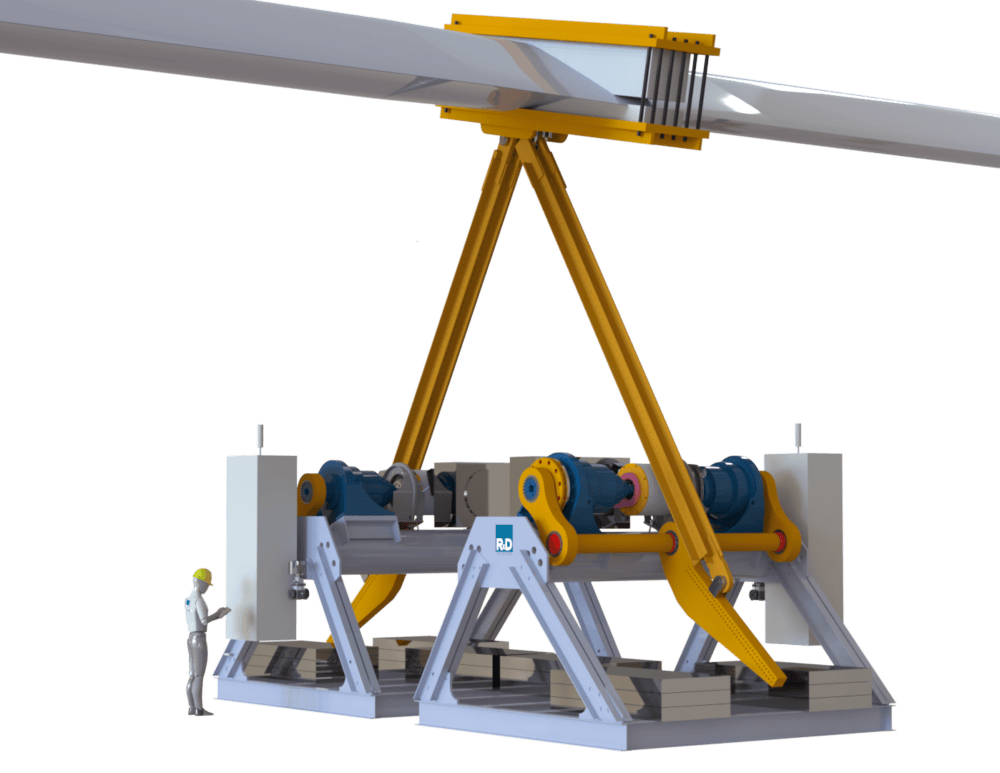

Blade fatigue exciter

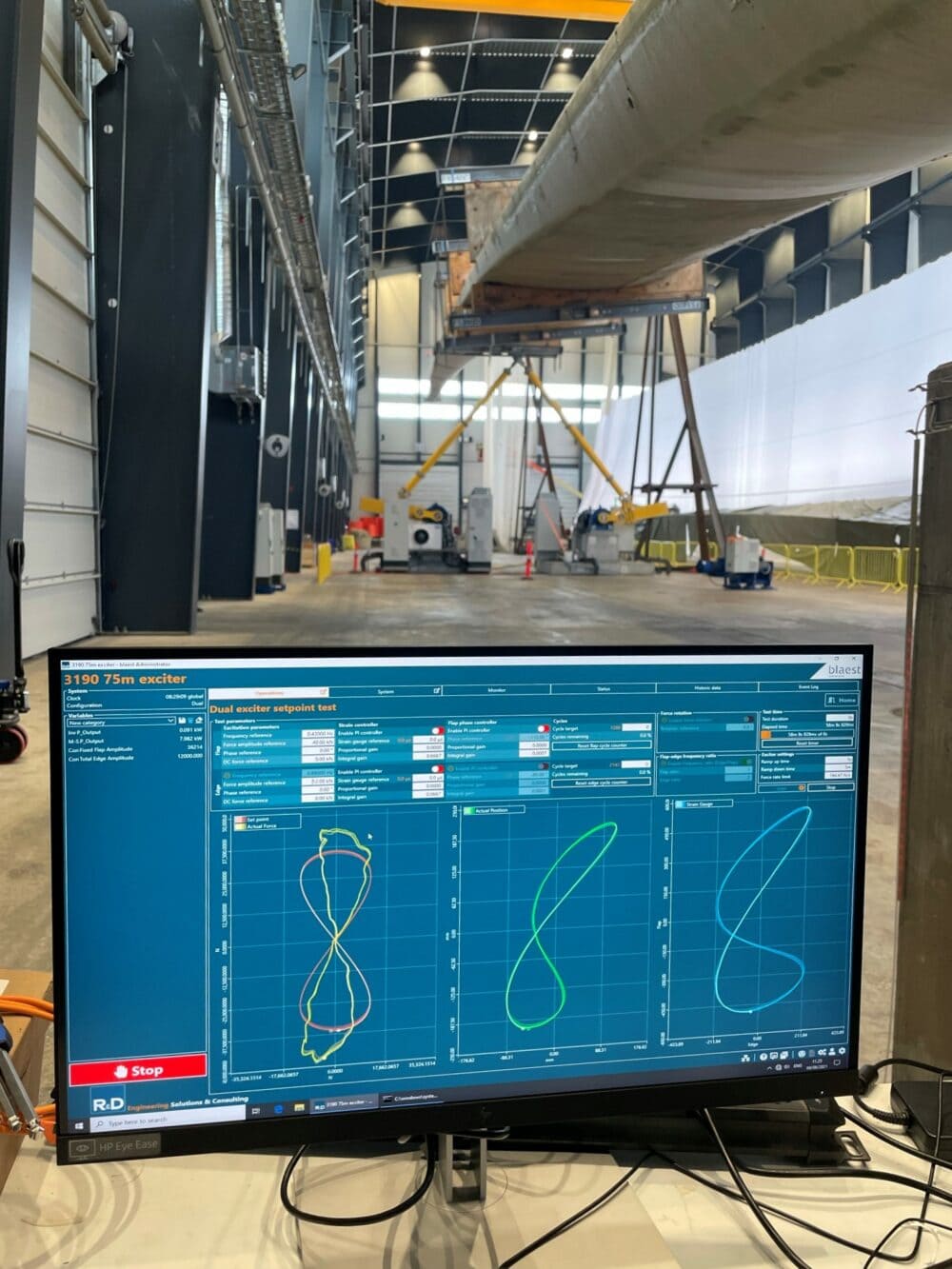

The testing solutions from R&D Test Systems enable you to verify your rotor blades according to the international standard IEC 61400-23. It is a modularized test system that can simultaneously apply flap- and edgewise loads. This reduces customers' time to market, as the changeover time can be omitted. The test system can be used as a single unit to test flap- or edgewise fatigue. Or, two units can be used in combination to achieve dual-axis functionality or extremely large loads in one direction.

This allows for a more realistic fatigue test. The test system introduces all the benefits of an electrical drive system, such as high efficiency and accurate control.

Our patented backlash-free system also eliminates typical backlash issues in traditionally geared transmissions, ensuring smooth operation and load application. The exciter system is an all-onboard unit that only requires an electrical connection, making it very agile and easy to integrate

We have developed a full-scale multi-axis fatigue blade test system that can test blades up to 130 meters. So far, the test system has been sold to Blaest in Denmark, WTTC in the US, and NWETC in China.

Specifications

R&D Test Systems: Blade fatigue exciter

See the dual-axis blade exciter in action, performing in flap-, edge- and chaotic mode for fatigue blade testing.

How can we help you?

For further information, please contact us