Case study

R&D delivers one of the world’s largest and most advanced test bench to LORC

Lindø Offshore Renewables Center (LORC) expands its range of test facilities with the addition of the new test bench, which tests the life-cycle of today’s largest wind turbines.

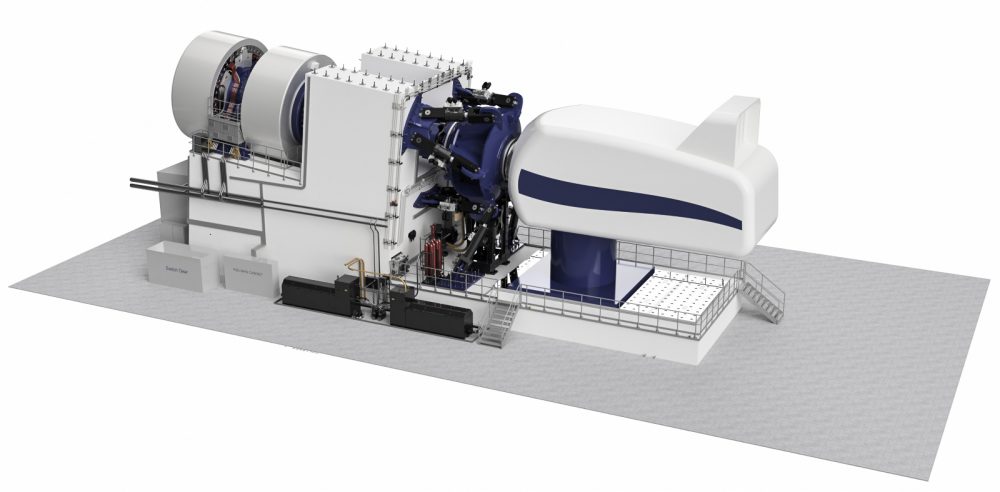

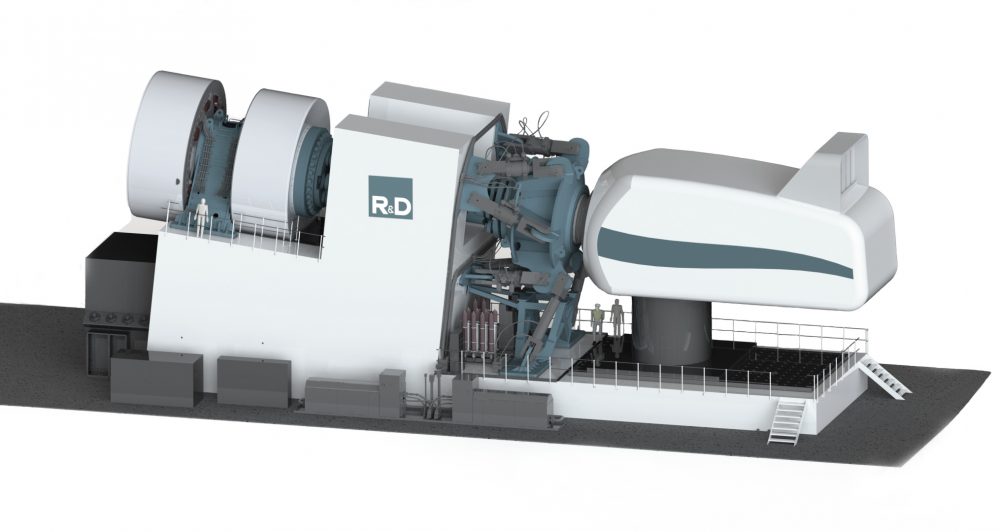

The engineering company R&D has built one of the world’s largest and most advanced test benches for Highly Accelerated Life-cycle Testing (HALT) of components for wind turbines up to 10 MW. The HALT test bench is an addition to Lindø Nacelle Testing, which is one of the largest indoor facilities for the testing of wind turbines in the Nordic countries. Among other things, the test centre houses a Function Tester capable of testing the entire wind turbine and the electrical system. The addition of the new HALT test bench enables wind turbine manufacturers to test the function and life-cycle of different wind turbines faster and better than ever before.

We have acquired one of the world’s largest and most impressive test benches in the industry, which will support the wind turbine manufacturers in the development of new wind turbines. I am confident that the test bench will help maintain Denmark’s leading position within this line of business.

Consolidates Denmark’s leading position within wind power

LORC’s new HALT test bench will serve as a contributing factor in securing Denmark’s leading position within the wind industry. “We have acquired one of the world’s largest and most impressive test benches in the industry, which will support the wind turbine manufacturers in the development of new wind turbines. I am confident that the test bench will help maintain Denmark’s leading position within this line of business”, Torben Lorenzen says, CEO of LORC.

The first customer has already signed a contract with LORC and will commence a series of tests shortly after the initiation of the test bench.

R&D has had a close collaboration with LORC in relation to the test centre. Besides the full responsibility of the HALT test bench, the engineering company has also been one of the main suppliers behind the Function Tester. “We are very pleased with the collaboration with LORC, both in relation to the development of the Function Tester and the HALT test bench. The test centre is important to the wind turbine manufacturers because it enhances their opportunities of testing and developing new wind turbines in Denmark”, Peter Kattai Ulrikkeholm says, Business Unit Director at R&D Test Systems.

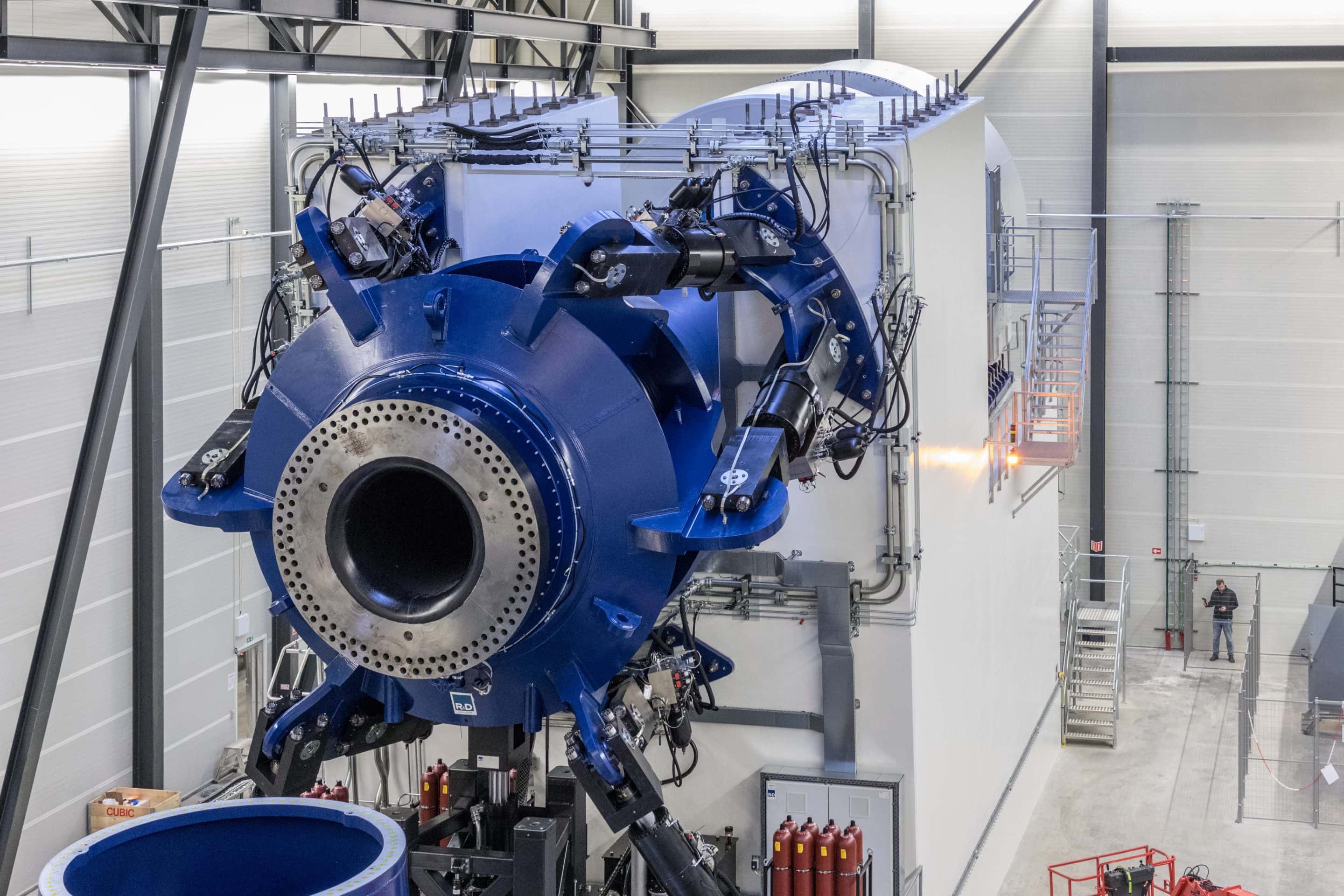

The development and installation of the test bench for LORC has strengthened R&D’s position in the market. “The development of the test bench is based on a detailed understanding of the system and specialised competences, which we have accumulated from our long-standing delivery of test benches”, Peter Kattai Ulrikkeholm says and continues: “When you construct one of the world’s largest and most advanced test benches, you are constantly faced with unknown factors. In this context, our broad experience and high level of competences within various engineering disciplines have been vital to our ability to deliver this high-quality test bench”.

Facts: A mechanical, hydraulic and electrical wind tunnel

The test bench has been developed for Highly Accelerated Life-cycle Testing of wind turbines and has a hydraulic Test Load Unit, which can add a bending moment of up to 25MNm to the test subject. In addition to this, the drive motor system and drivetrain can add a torque of 14.5MNm to the test subject. The hydraulic Test Load Unit operates as a wind simulator and can replicate the reactions of the wind on the main axle of the test subject using three forces, two bending moments and one torque level. Combined, the test bench is a large mechanical, hydraulic and electrical wind tunnel, which can simulate 25 years of service life in less than 6 months.

The foundation for the test bench is a reinforced concrete foundation with a volume of approximately 1500m3. The foundation requires 107 concrete piles driven 16 meters into the ground, more than 200 tons of reinforcing steel, 100 tons of steel plates for fixation of the test subjects and 300 steel bars to transfer the loads from the test bench to the test subjects.

In order to ensure an optimum running-in and performance of the test bench, all functions have been simulated. The simulation models and results have been used in the software development and training of the operators. By means of the user interface, all test scenarios can be specified and supervised and all results can be stored for further analysis.