Case study

R&D collaborates closely with Aalborg University on developing a more energy-efficient wind load test

The testing of 25 years of wind load on an 8MW offshore wind turbine requires a considerable amount of energy. R&D and AAU are collaborating on a more realistic and energy-efficient test, which will result in cheaper green energy to the consumers.

The collaboration between R&D and the researchers from Aalborg University (AAU) will last three years. The project is supported by EUDP (the Energy Technology Development and Demonstration program) which is an initiative by the Danish Energy Agency aimed at making Denmark independent of fossil fuels in the future.

Eight employees from R&D and four from Aalborg University are appointed to the project. In the course of three years, the two collaborators will deliver 10 years of work on the project altogether. The total budget is approximately 12 million DKK.

This project is very interesting for the university. The project complements the intensive research related to the wind turbine industry conducted at the Department of Energy Technology.

Reduced energy consumption

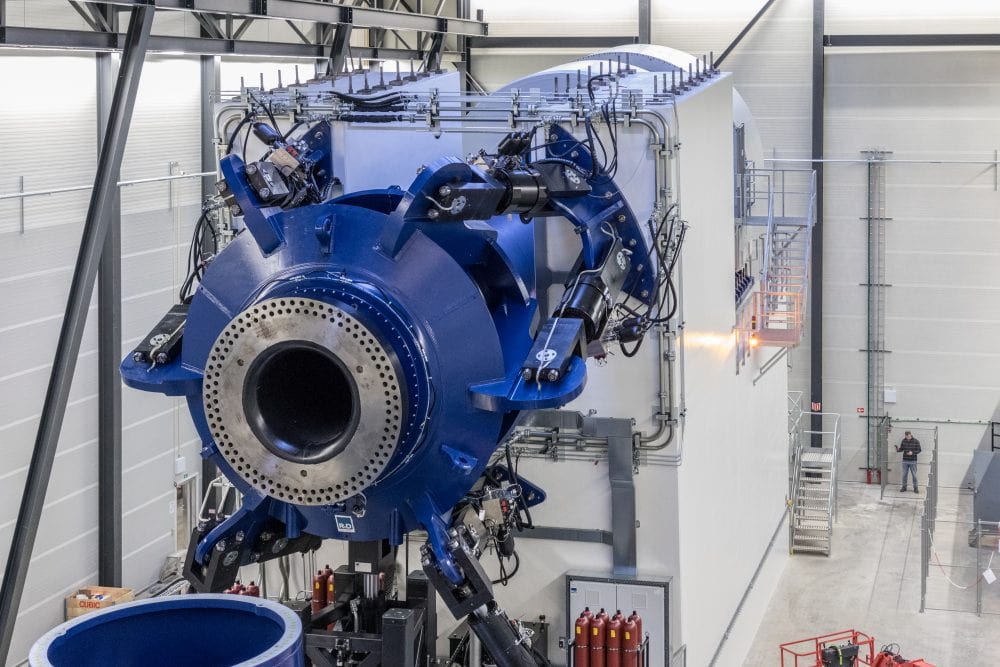

Jes G. Andersen is a civil engineer at R&D in Aarhus and the project manager of the development project. For several years, R&D has been one of the world’s leading companies when it comes to developing test systems for wind turbines. During this project, R&D is working on developing a loading unit for a new test system for wind energy in close collaboration with internationally prominent capacities from Aalborg University at the Department of Energy Technology.

”The goal is to develop a test system which conducts the tests as realistically as possible, keeps the test time at six months or less while consuming less energy than other test systems do today,” Jes G. Andersen explains.

Jes has previoulsy worked at Vestas and has many years of experience with research projects and collaboration with technical universities.

The price of electricity from wind turbines is the crucial factor for the continued distribution of wind energy. Especially offshore wind energy is challenged by factors such as the high costs of installation and establishment of the foundation. Among other parameters which affect the price of the electricity are the price of the turbine and the price of service and maintenance during the entire lifespan of the turbine. Therefore, it is important that the testing of the wind turbines can be conducted at a reduced price and still be as reliable and realistic as possible.

More realistic tests

Today, most tests concerning the lifetime of wind turbines are conducted by exposing subsystems or individual systems in the turbine to simplified cyclic load conditions. The main purpose of the project is to change the load conditions which the turbine is exposed to into a more realistic form. The researchers from AAU and the employees from R&D will collaborate on developing a load condition unit which can reproduce the exact load conditions which the turbine is exposed to in nature – a sort of mechanical wind tunnel for wind turbine tests. By exposing the turbine to realistic load conditions, the hope is that it will be easier and also cheaper to detect and remove the typical flaws before the product is launched.

”Today, there is a tendency towards test load conditions being so simple that they provoke flaws which might not have occurred in real life. The identified flaws are simply not the right ones. The more realistic the load conditions are, the bigger is the possibility of finding the flaws and errors which might become problematic and expensive later on,” Jes G. Andersen says.

More reliable tests at a lower price

The researchers from Aalborg University and the employees from R&D expect that the outcome of the collaboration will benefit the reliability and the price of the turbines. In the end, this benefits the customers by reducing the price of electricity from wind turbines.

”This project is very interesting for the university. The project complements the intensive research conducted at the Department of Energy Technology related to the wind turbine industry. Furthermore, the competences required to develop the test system are within the prioritised research field in ”The Fluid Power and Mechatronic Section”, professor and Ph.d. Torben O. Andersen from the Department of Energy Technology at Aalborg University says.

”A collaborative project of this kind ensures great freedom for research and development. We can use our extensive knowhow from R&D's business field of test systems and at the same time spend the required amount of time immersing in the subject, while the participants from AAU can use their scientific experience. When we unite our competences, it creates a very strong synergy,” Jes G. Andersen states.

The first scale model for verification of the project is expected to be ready in Aalborg in the summer of 2015.