Civil Engineering

Civil Engineering

Building the unshakable

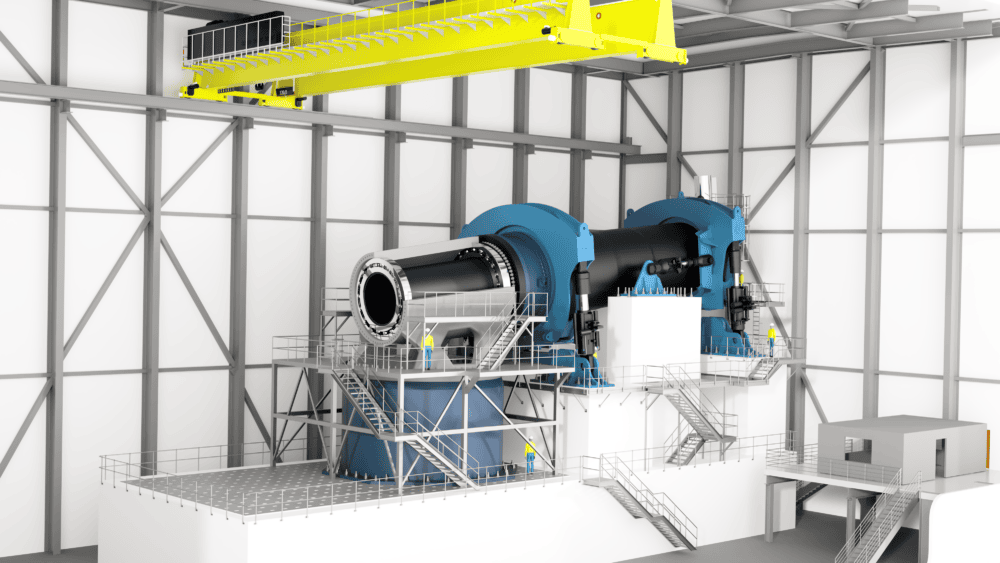

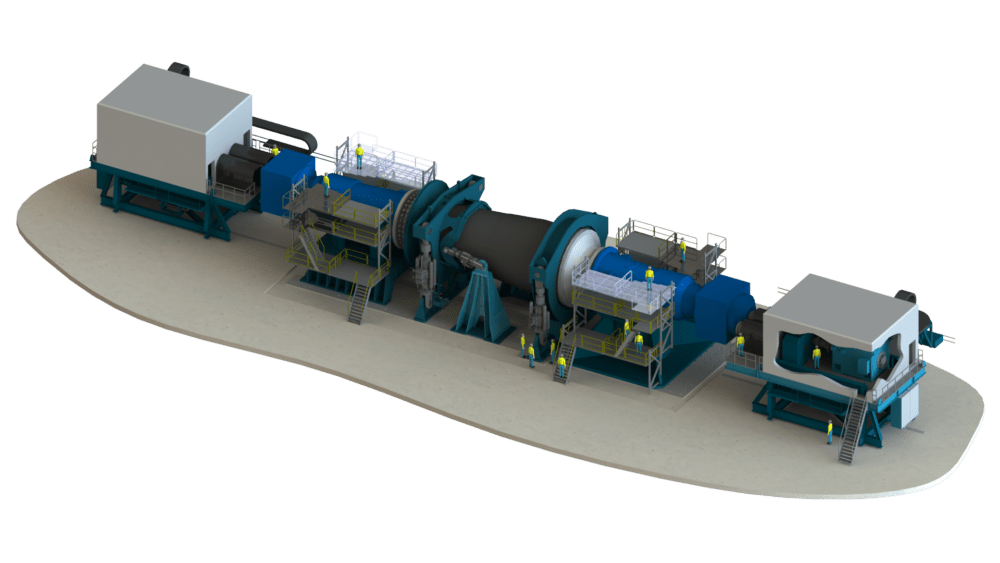

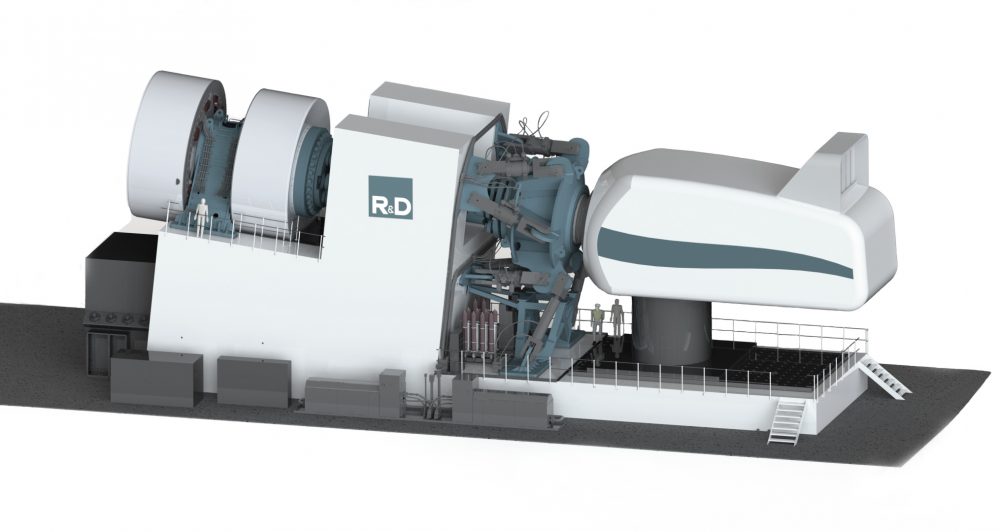

When testing the latest generation of wind turbines, you need more than just advanced test equipment. The foundation plays a critical role in ensuring accurate results, reliability, and safety. At R&D Test Systems, our civil engineering expertise ensures that test bench foundations can withstand the extreme forces generated during testing.

We design strong floors, reaction masses, and heavy-duty machine foundations, ensuring seamless integration with each client's testing requirements and site conditions. Our approach utilizes precise FE analysis, rigid body modeling, and advanced clamping technologies—such as steel plates and anchor systems—to deliver durable, high-performance structures that withstand extreme dynamic loads.

The backbone of reliable testing

With over 15 years of experience in concrete structural analysis and fatigue-driven design, we specialize in:

- Geotechnical support structure design

- Pit construction design and soil pressure analysis

- Vibration, behavior, and stiffness analysis

- Fatigue-driven concrete design

- Cooling system design for large concrete structures during hardening

- Machine steel interface and heavy-duty anchor system design

- Layout of stairs, railings, and platforms

Our design expertise

Our geotechnical support structure design uses site-specific survey data to create an optimized foundation solution. We ensure stability and integrity across all load scenarios through detailed geotechnical analysis and load assessments, securing foundation performance under any operational condition.

A pit, composed of reinforced concrete slabs and walls, protects the machine foundation from the surrounding environment. Its design addresses temporary loads during construction and permanent loads once the machine foundation and facility floor are in place. Ground anchors are used to support the pit walls for deeper pits or where groundwater and soil pressure are significant.

The machine foundation can be isolated from its surroundings using a vibration damping system, creating a floating foundation separate from the geotechnical support structure. The damping system is chosen based on vibration criteria, pressure ranges, and environmental requirements. Therefore, to select the most efficient damping system, FEM simulations of the machine foundation behavior are conducted.

A machine foundation is a critical, fatigue-driven structure, exposed to significant dynamic forces and requiring precise design. Unlike standard concrete structures, it demands specialized stress and deformation analyses using advanced engineering tools. R&D Test Systems provides accurate data on foundation stiffness and strength, ensuring a robust design optimized for peak performance.

With extensive global experience in machine foundation construction, we meticulously design complex reinforcement layouts, anchor integration, and machine interfaces for buildability and quality. Additionally, to manage high heat during curing, we incorporate temporary cooling systems, supported by our expertise in concrete temperature analysis, ensuring the structure’s integrity from the outset.

Machinery is secured to the foundation’s steel interfaces with post-tensioned anchors. R&D Test Systems has developed both replaceable and cast-in anchor solutions for heavy-duty machinery. Each anchor system undergoes rigorous design checks to ensure stability and prevent any movement during operation, keeping the machinery firmly clamped to the foundation.

For large, complex machinery requiring specialized access for operation, service, and maintenance, we provide 3D layouts and production drawings for stairs, railings, platforms, and related features.

Feasibility studies and conceptual design

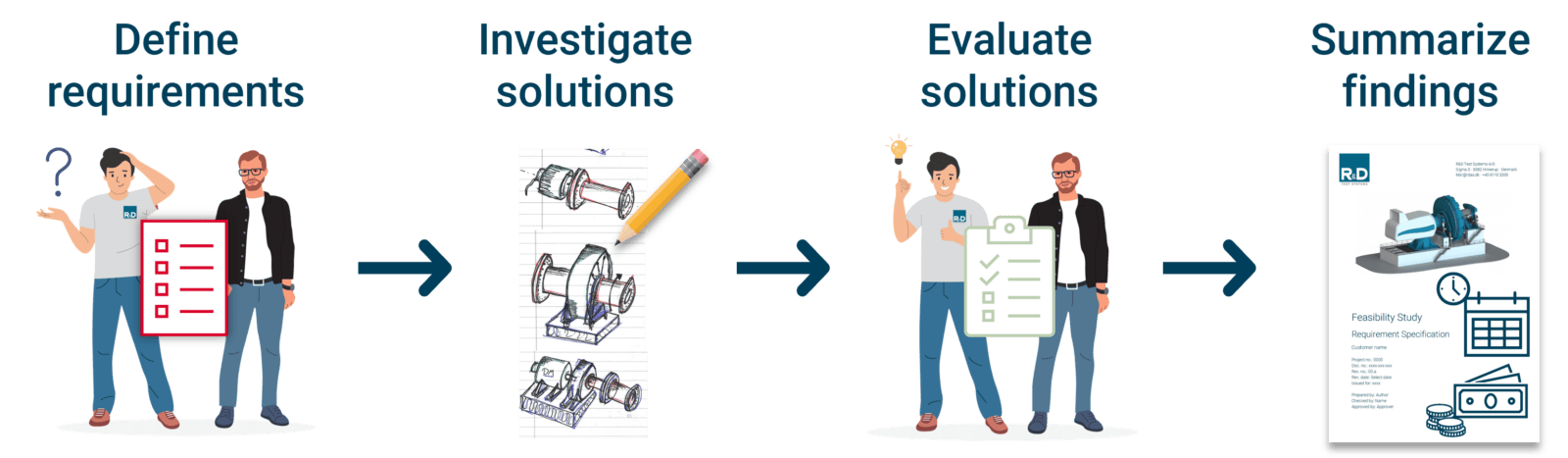

Feasibility Studies: Our feasibility studies thoroughly evaluate technically and financially viable foundation solutions tailored to your specific site conditions and machine requirements. Working closely across engineering disciplines, we assess design options and compile key specifications into a clear requirements document. In a client workshop, we present each solution's benefits, risks, and quality considerations to support informed decision-making. A comprehensive feasibility report summarizes these findings, creating a solid foundation for the next project phase.

Conceptual Design: Once the optimal foundation solution is chosen, we develop a complete conceptual design that finalizes the layout, foundation dimensions, subsystems, and interfaces. This phase includes evaluating site conditions, geotechnical investigations, and load distribution to determine the most suitable soil support structure (e.g., pile support, ground anchors, pit construction, or soil exchange). All design information is compiled into a detailed design description, covering the foundation layout, each subsystem, execution strategy, and overall design features. A 360° technical review ensures a robust and well-rounded approach to the proposed solution.

How can we help you? Let's have a chat