Test Systems

The most powerful end-of-line test bench

The most powerful end-of-line test bench

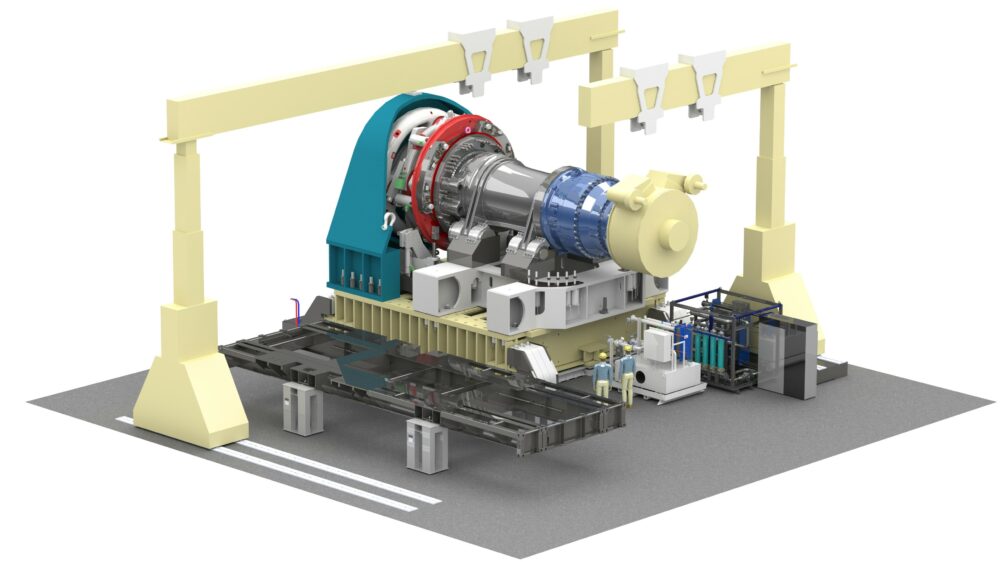

R&D Test Systems wins follow-up order for the most powerful end-of-line test bench for ZF Wind Power.

- The test rig performs final tests before shipping of offshore powertrain, including gearbox, generator, and main bearing arrangement

- Automated link-arm-coupling concept reduces mounting time by up to 90 percent; two units tested per day

- End-of-line tests ensure the quality and performance of the final system before commissioning

- The motor can operate at more than 15 MW, making it the most powerful end-of-line wind turbine test bench

R&D Test Systems, a leading Danish wind turbine test system supplier, has received a follow-up order from ZF Wind Power to develop and deliver a new end-of-line test bench needed to verify the system functionality on manufactured powertrains, including the gearbox, generator, and main bearing arrangement, prior to shipping to the OEMs. The test rig, which features R&D Test Systems' automated concept based on link-arm coupling, reduces mounting time by up to 90 percent, thus allowing two powertrain units to be tested per day.

The end-of-line test rig will be delivered to ZF Wind Power’s production plant at Lommel, Belgium, in autumn 2023. R&D Test Systems was also selected early in 2022 to supply a 30 MW validation test bench for ZF Wind Power’s Test & Prototype Center at the same site.

“We are very pleased to be awarded this additional contract and to partner with ZF Wind Power on two of the most powerful test benches. This is a recognition of our competences in developing test systems for testing high-power offshore wind turbines both at the production and the prototype level,” says Peter Ulrikkeholm, CEO, R&D Test Systems.

Performing the final tests before the powertrain leaves the factory, end-of-line tests ensure the quality and performance of the final product. “An end-of-line test cycle will check the function of the system under load, testing hydraulics, sensor connections, as well as contact patterns for the gears, in addition to checking lubrication, temperature, pressure and noise and vibration levels,” explains Martin Knops, Chief Technology Officer (CTO) of ZF Wind Power. A final flushing of the gearbox makes it ready to run from day one.

The gearbox is one of the most complex parts in a wind turbine due to the many dynamic interacting sub-systems. The whole powertrain therefore requires a series of final, high-load tests before going into the field. “We believe once this test rig is up and running, it will be the most powerful end-of-line test rig in the wind power industry,” explains Peter Winther, Key Account Manager at R&D Test Systems.

The test rig for ZF Wind Power conducts load tests, powered by the more than 15 MW motor, providing an impressive 18 MNm of torque to test the unit at high load levels. “This final test ensures that the powertrain with all its connections works as it should, even when exposed to 5000 times the torque of Formula 1 cars,” adds Peter Winther.

Capable of lifting up to 300 tons, the crane selected for the test bench will both lift and precisely place the offshore powertrains in the test bench, which at the highest point is six meters above ground. Three automated hydraulic systems then clamp the powertrain in place with the link-arm-coupling thereby connecting the test motor to the powertrain.

“Mounting of a powertrain this size is time-consuming as there are literally hundreds of connections that need to be made, both mechanical and high and low power electrical. Our design includes a complete high-voltage drive system with an automated connection solution that will optimize the process of installing the powertrain.

“Dismounting and disconnecting the verified unit will similarly benefit from the automated process. This saves manual work and is a major advantage for end-of-line testing when production flow is of high importance. The concept allows us to test two units a day,” concludes Peter Winther.

R&D Test System will be using its proven automated link arm concept designed to connect the 15 MW motor and the powertrain unit, which must be robust enough to cope with the huge loads while still being sufficiently flexible to allow quick changeovers.

The engineering team consisting of software, mechanical, low-voltage, high-voltage, civil and hydraulic specialists have already started the development of the end-of-line test bench at R&D Test Systems’ Headquarters in Hinnerup near Aarhus in Denmark. The company will be applying its test bench expertise in high-power drivetrain testing of offshore wind turbines.