Insights

R&D will help improve the longevity of wind turbine blades

In the following three years, representatives from DTU Wind Energy, DMI, E.ON, R&D, Vattenfall and Vestas will work on the project "EROSION – Wind Turbine Blade Erosion: Reducing the Largest Uncertainties".

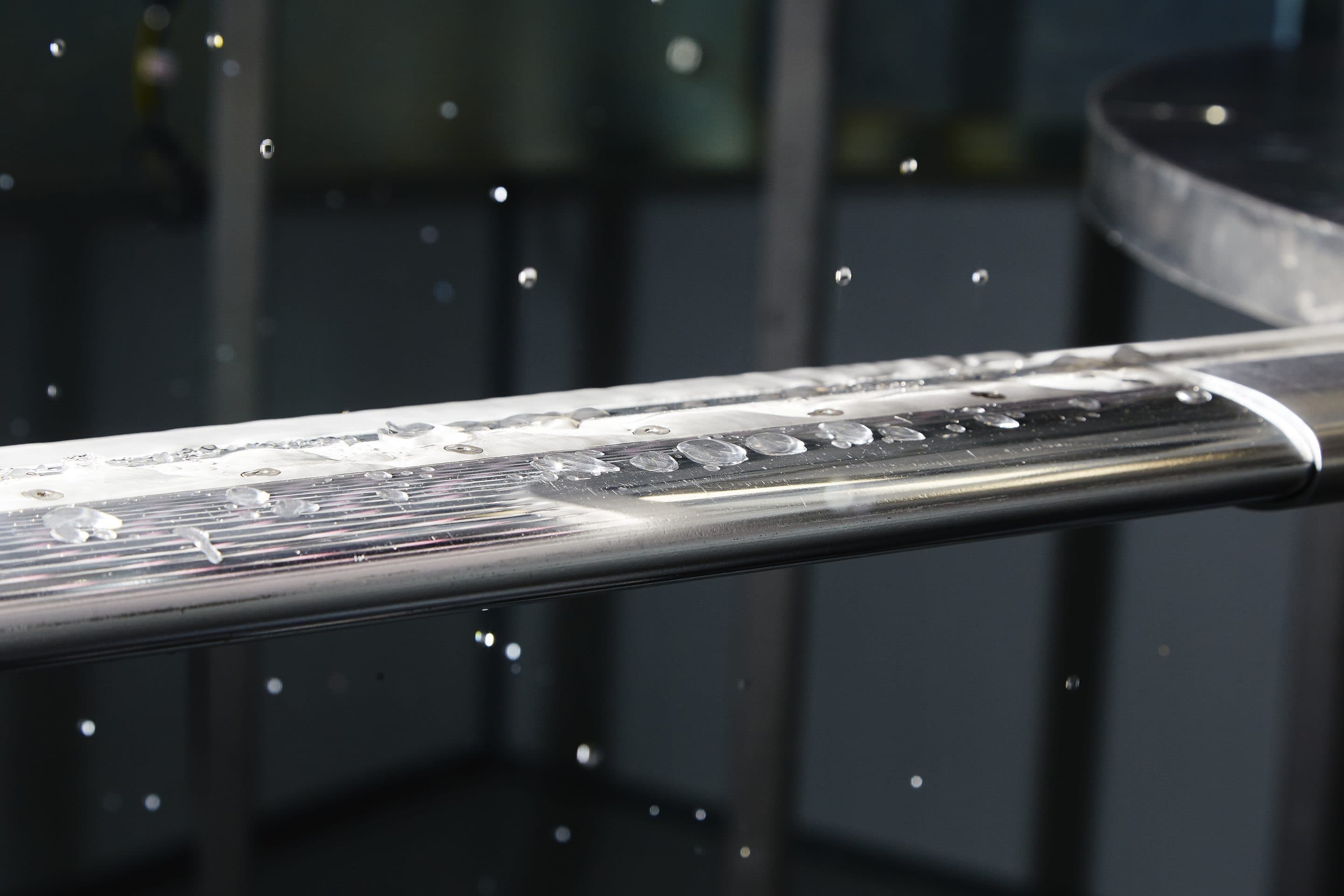

As it is today, the leading edges of wind turbine blades often have to be repaired due to weather conditions. The group behind the project will work on changing the way wind turbines are used in order to improve the endurance of the blades.

”Today, more than 40% of the energy in Denmark derives from wind turbines. However, there is a problem with the blades in relation to wind and weather. Unfortunately, there is not anything that can solve the problems at the given moment. It is expensive to maintain wind turbines. That is one of the reasons why we now look into what we can do to improve the longevity of wind turbine blades,” Charlotte Hasager says, Project Manager and Senior Researcher at DTU Wind Energy.

Energy improvement

The group behind the project has a very ambitious goal; to reduce the amount of time that wind turbines are out of operation due to erosion-induced errors. The outcome should be a cost reduction of more than 10 million DKK each year for a 400 MW wind farm.

E.ON and Vattenfall are two large companies that produce a great amount of energy from wind turbines. They both participate in the project to find new ways of limiting erosion. DMI contributes with knowledge of wind and weather. Furthermore, Vestas is the largest producer of wind turbines and they are interested in improvements. R&D is specialized in testing materials such as wind turbine blades and their contribution to the project entails laboratory testing.

Source: http://www.vindenergi.dtu.dk/english/News/Nyhed?id=6d35bb71-c2e2-4191-af73-1c65eb255345