Digital Solutions

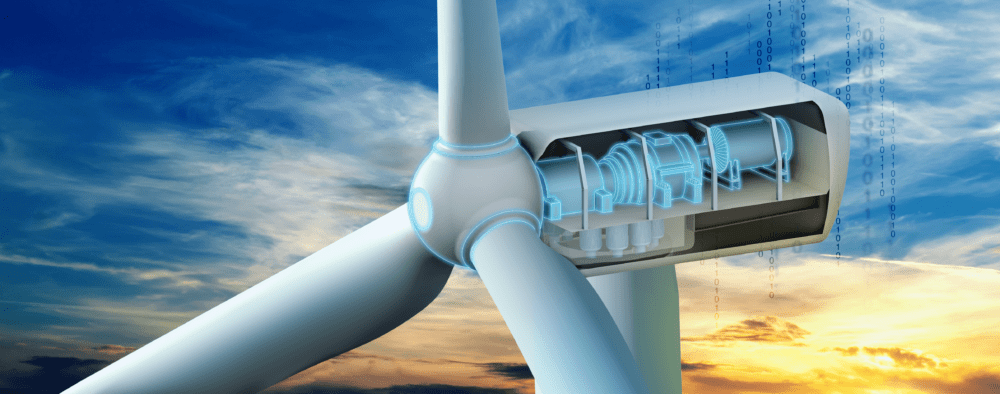

Advanced simulation in wind turbine testing: Integration of cyber-physical systems and complex digital twins

Advanced simulation in wind turbine testing: Integration of cyber-physical systems and complex digital twins

New types of wind turbines must be thoroughly tested before they are placed in production. However, it becomes increasingly expensive and time-consuming as the turbines and their components become larger and more complex.

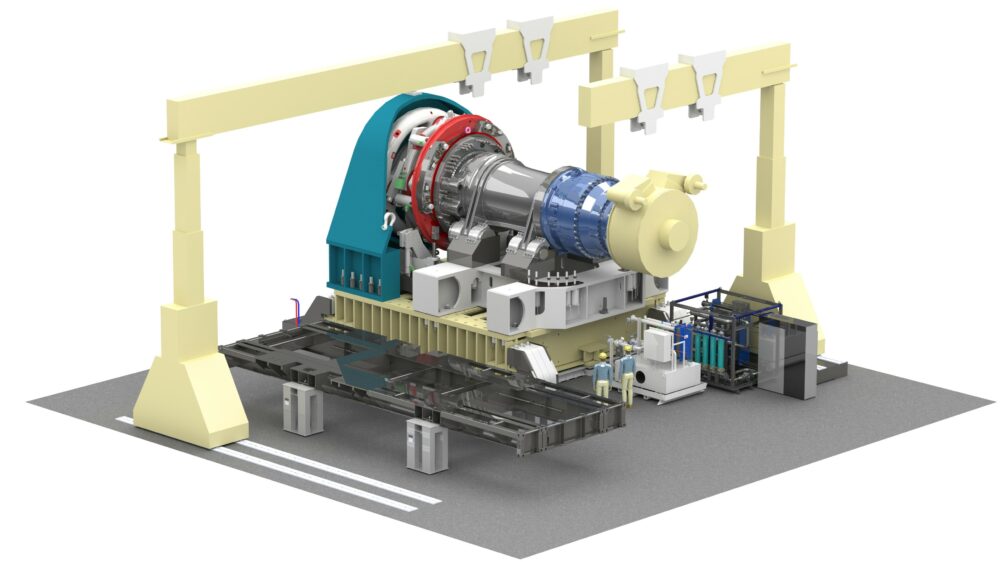

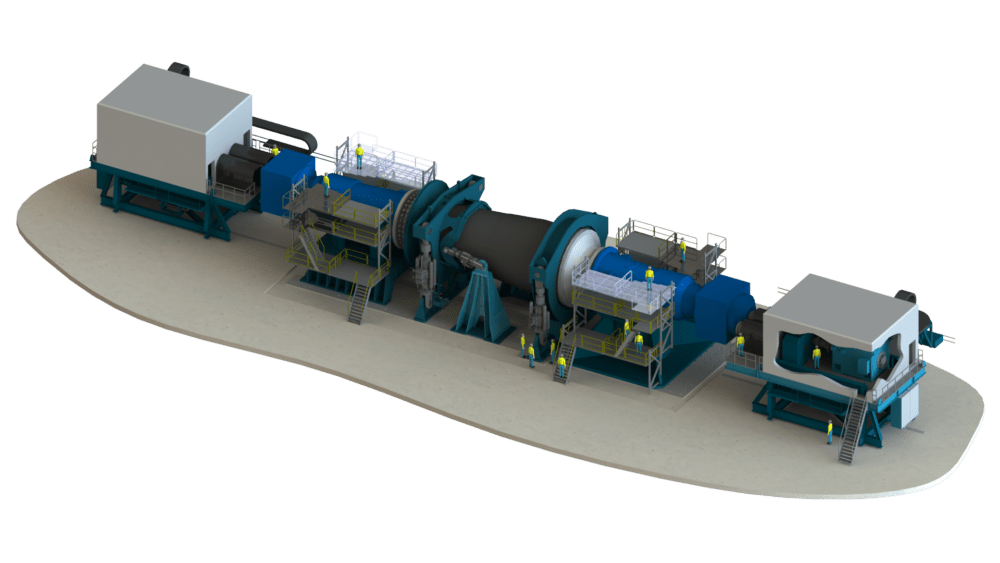

R&D Test Systems aims to simulate that problem away. Here, one digital twin is not enough. Many are needed. At R&D Test Systems, 170+ engineers are building colossal test benches in steel and concrete with huge engines that destroy a turbine prototype in a few months through 20 years of simulated wind and weather.

The digital dimension is growing

However, the test benches are not only raw power and many hundred tons of steel and concrete. Their digital dimension is growing in scope and complexity, and Elif Ecem Bas is one of the main characters in that work. As an expert in hybrid testing with a Ph.D. in structural engineering, she manages the research projects in which the company participates. The research focuses on splicing the physical test bench and digital models into what is called a cyber-physical system.

The aim is to reduce the time a prototype spends on the rack. Furthermore, the precision of the tests carried out will be increased. Last but not least, you simulate not only nacelles and turbine components but also the full test bench to predict wear and potential damages to the test bench before they occur.

Not one model, but many

"When we talk about a digital twin, it's not one model, but many," explains Elif Ecem Bas. "We combine the models, depending on the application we’re working with."

Different digital twins come into play depending on which use case is in focus. For example, Elif Ecem Bas and her team have developed a twin for simulating test sequences that, in advance, can eliminate faulty tests. Here, the twin consists of dynamic models of the test bench, including the components, and a model of the subject being tested, also called a “DUT” (device under test).

Another type of application is 3D visualization. Here, there are no dynamic models in play. You can make do with a 3D CAD model and selected sensors and indicate a data flow throughout the sensors.

Twin of the actual test bench

"We have a separate digital framework for the test bench itself. With this, we can predict how different test sequences affect the bench and its components. We can use this knowledge, e.g., to choose which types of tests we go through with. Let’s say that the model shows that two different tests give the same result, but one strains the bench much more than the other. So we can choose the test sequence that cuts the least possible of the bench's life."

According to Elif Ecem Bas, R&D Test Systems is ahead with digitizing and simulating wind turbine tests because they develop and build test benches from scratch. Everything is designed in-house, including foundations, reinforcement, motors, controls, and all the other components that make up a test bench. The largest is up to 60 meters long and equipped with two 30 MW low-speed motors providing 45 mNm.

Digital twin: yes, please. It just has to be a secret.

R&D Test Systems has a challenge: They design the test systems but don't perform the actual tests. Furthermore, they have nothing to do with the drivetrains and components being tested. This is a problem: to achieve the best results of the simulations for all parties, it is necessary to combine the different models in play, e.g., the model of the test bench and the model of the new type of wind turbine being tested. However, the OEMs are not interested in sharing the model of, e.g., a new product, and thus their IP rights.

This challenge is solved with what, in the technical language, is called FMI-based co-simulation. FMI stands for functional mockup interface. It's a free standard that defines an interface for the exchange of simulation models between different actors. The FMI is a “black box” that makes it possible to specify input and output from the model while information about the actual model remains a secret. This allows you to simulate synchronized systems, in this case, a model of the test bench and a model of the test subject.

The FMI also makes it possible to correlate models based on different simulation environments and different types of software.

Everything is mirrored digitally

Every physical piece of the test bench is mirrored in the digital world.

"We take the models and feed them with real-life data. At the same time, we design interfaces for the additional models in our digital twin platform, e.g., the wind turbine manufacturer's model of the component or drivetrain tested. Thus connecting the models to get the necessary precision. We have a clear advantage here because our share of the linked models is so detailed and constant.”

Elif Ecem Bas recognizes that digital twins are complex, especially in R&D Test System's case, which has almost a full football team of twins. This makes it necessary to be up to date with the latest knowledge in the field. Hence, R&D Test System participates in research in the area.

Together with the Department of Electrical and Computer Engineering and the Department of Civil and Architectural Engineering from Aarhus University, R&D Test Systems are working on the research project DIGIT-BENCH (Digital Twin for Large-Scale Test Benches for the Wind Industry) that aims to replace physical tests with digital. It is expected to reduce the test time by 20%. The project is financed by The Energy Technology Development and Demonstration Program (EUDP), a Danish public grant scheme that supports the development and demonstration of new energy technologies.

In collaboration with DTU Wind, a similar project, BLATIGUE-2, aims to develop simulation software for stress testing of wind turbine blades.

It is essential for Elif Ecem Bas that the research she is involved in can be translated into something useful. The results must benefit the users of the company’s test benches and thus be relevant in a commercial context. It must not be so complex that it cannot be used in the customers' workday. This is ensured, e.g., by having the Danish wind turbine test center LORC among the participants.

Good advice from the expert

Elif Ecem Bas has some good advice for companies considering whether they should look into digital twins: Try not to build one model containing everything. It can easily go wrong. Think modular and flexible instead. Choose an area that is important to your organization and which is manageable. Build a model that works. From there, you can move on to the next building block and gradually build the simulation, which is becoming increasingly more comprehensive.

(The article was originally published in the Danish magazine Ingeniøren.)

How can we help you?