Bolt-Check

A new era of wind turbine bolt installation and service: R&D Test Systems and Panasonic TOUGHBOOK

A new era of wind turbine bolt installation and service: R&D Test Systems and Panasonic TOUGHBOOK

A new era of wind turbine bolt installation and service

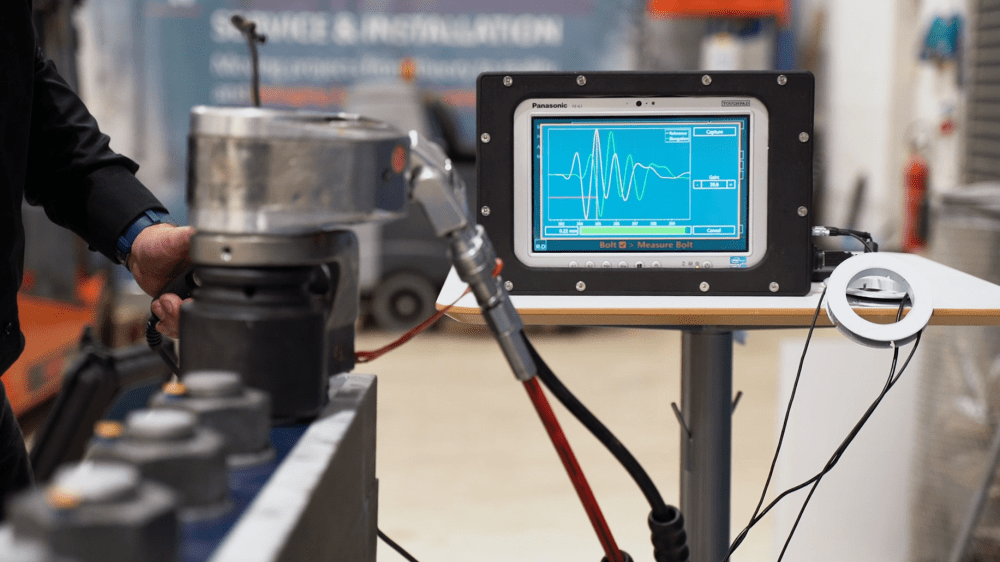

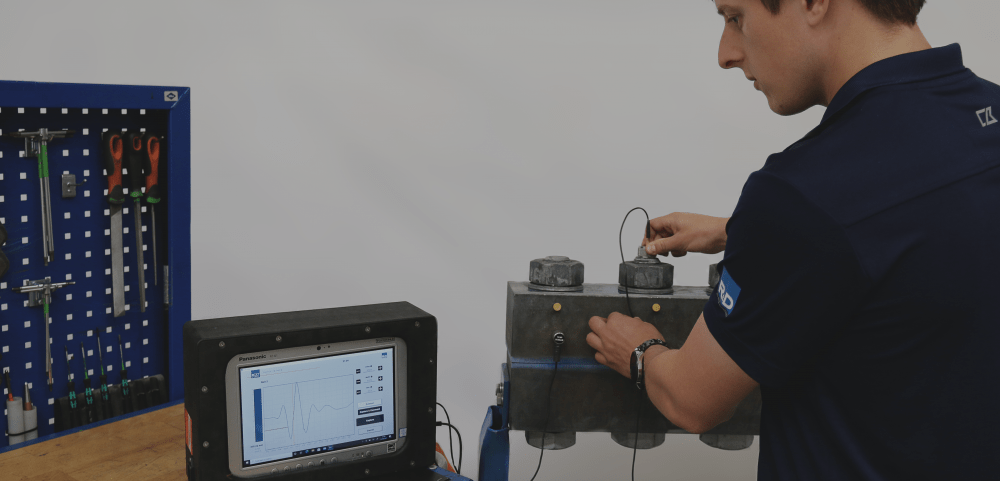

Maintaining the structural integrity of wind turbines and up to 10,000 bolted joints is essential for ensuring their efficiency and longevity. Danish technology company R&D Test Systems has addressed this challenge with its ultrasound measurement device Bolt-Check, integrated with Panasonic’s TOUGHBOOK G2 2-in-1 detachable tablet.

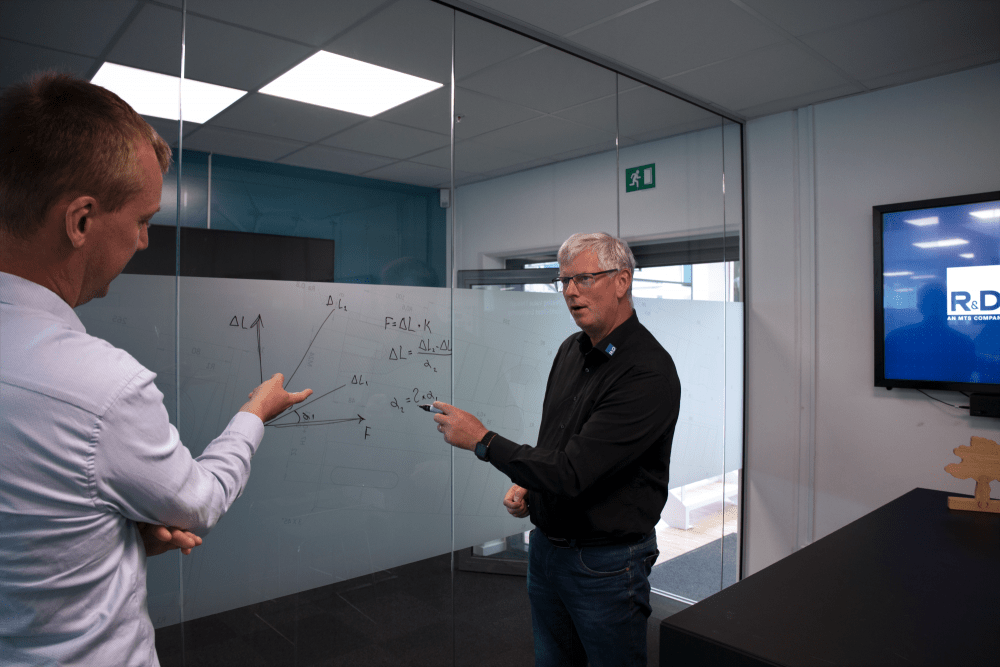

For decades, engineers have faced significant challenges in tightening wind turbine bolts to precise specifications. Traditional manual approaches rely heavily on physical measurements and are prone to human error. This presents a critical risk in structures where precision is paramount.

Jesper Stokbæk, Specialist at R&D Test Systems, emphasizes the severity of the issue: “With today’s manual processes, the industry has accepted up to a 30 percent margin of error. We have even measured up to 70 percent inaccuracy when tightening bolts manually.” Such discrepancies can lead to operational inefficiencies or, in extreme cases, catastrophic structural failures.

The Bolt-Check Solution

R&D Test Systems has developed a groundbreaking solution: the Bolt-Check tool. By leveraging ultrasound technology, this tool measures the condition of bolted joints with unmatched accuracy. The digitization and streamlining of the bolt-tightening process provide significant advantages:

- Enhanced precision by replacing manual tensioning with data-driven insights reduces errors

- Cost efficiency as only bolts requiring adjustment are tightened, saving time and resources

- Improved uptime as proactive maintenance ensures turbines remain operational longer

The use of Panasonic TOUGHBOOK G2

To maximize the efficiency of the Bolt-Check solution, R&D Test Systems partnered with Panasonic TOUGHBOOK.

Jesper Stokbæk highlights the importance of this partnership: “The ability to customize the TOUGHBOOK G2 to our desired specifications is just what we were looking for. We also required a rugged and reliable device that could work in the harsh environments of wind farms; the G2 can withstand drops, bumps, vibrations, and water splashes, giving us peace of mind that productivity won’t be affected. They keep working no matter what, which is absolutely crucial.”

R&D Test Systems’ Bolt-Check software, supported by Panasonic TOUGHBOOK, represents a significant step forward in wind turbine maintenance. By improving accuracy, reducing costs, and addressing labor challenges, this innovation contributes to making sustainable energy more accessible and reliable.

Learn more about this breakthrough in wind turbine technology and the role of Panasonic TOUGHBOOK by reading the original case story on Panasonic’s website.

Watch case video here

Want to know more?