Digital Solutions

Close the gap between simulation and testing

Close the gap between simulation and testing

Digital Solutions

- Hardware-in-the-Loop (HiL): Seamlessly integrate your simulation models into real-time systems for accurate testing.

- Grid Emulation: Simulate electrical grid conditions on your test bench to validate your system’s performance and grid compliance.

- Hybrid Testing: Combine physical and virtual testing for enhanced accuracy and flexibility.

- Simulation Solutions: Optimize your development process with advanced simulation tools.

- Data-Driven Solutions: Harness the power of data to improve testing efficiency and outcomes.

Realistic testing enabled by HiL Systems

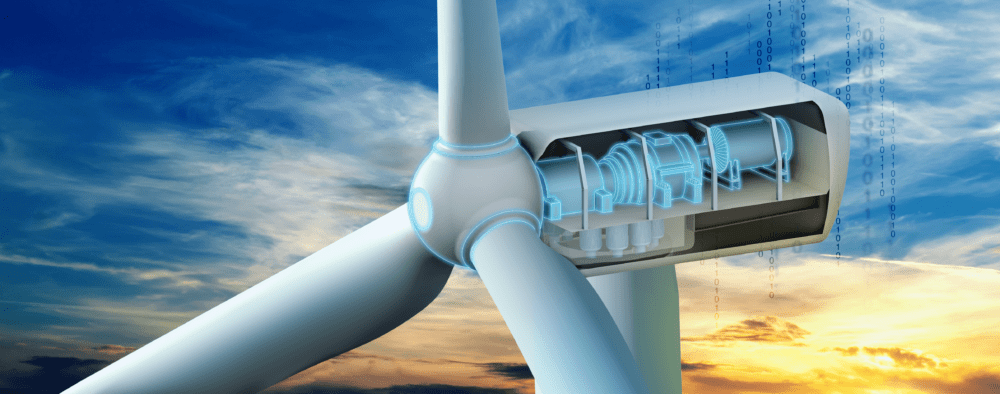

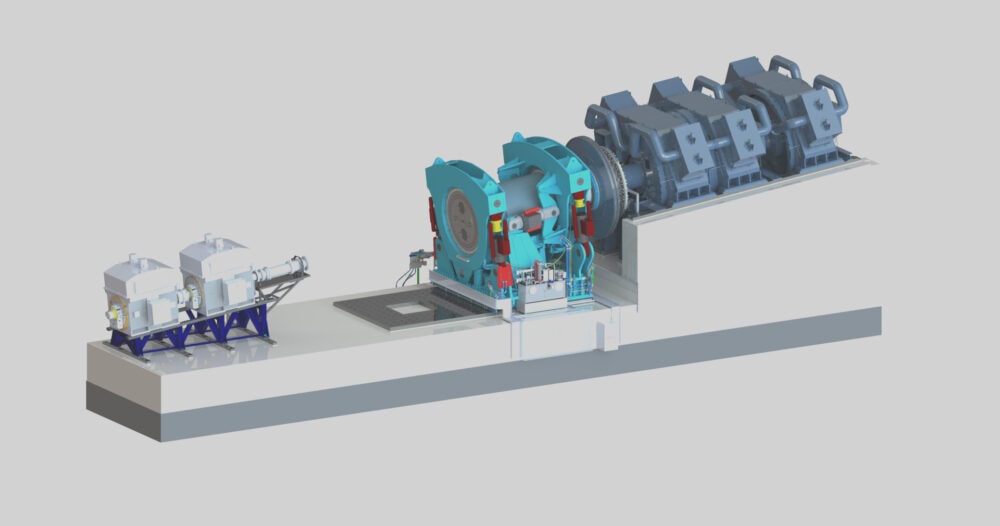

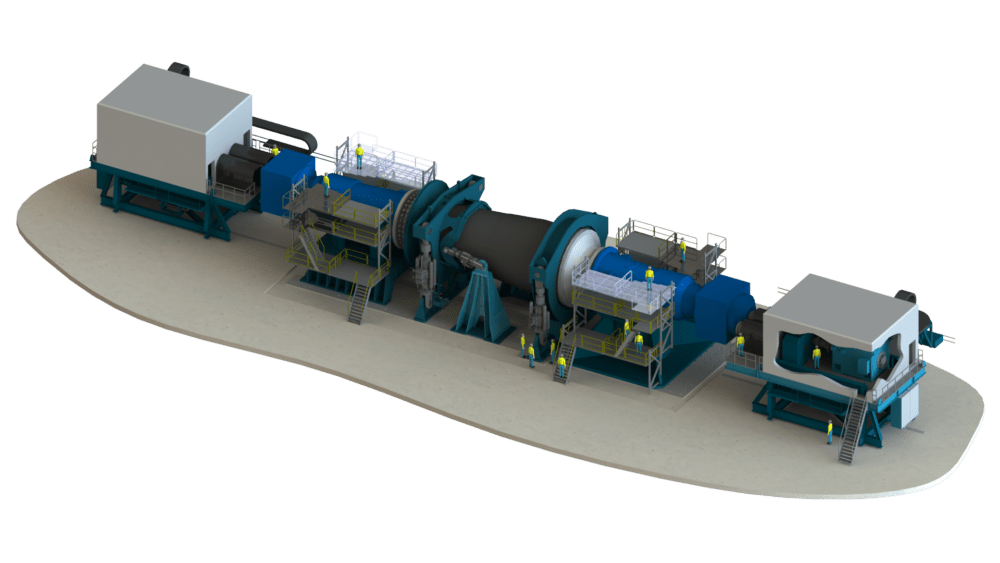

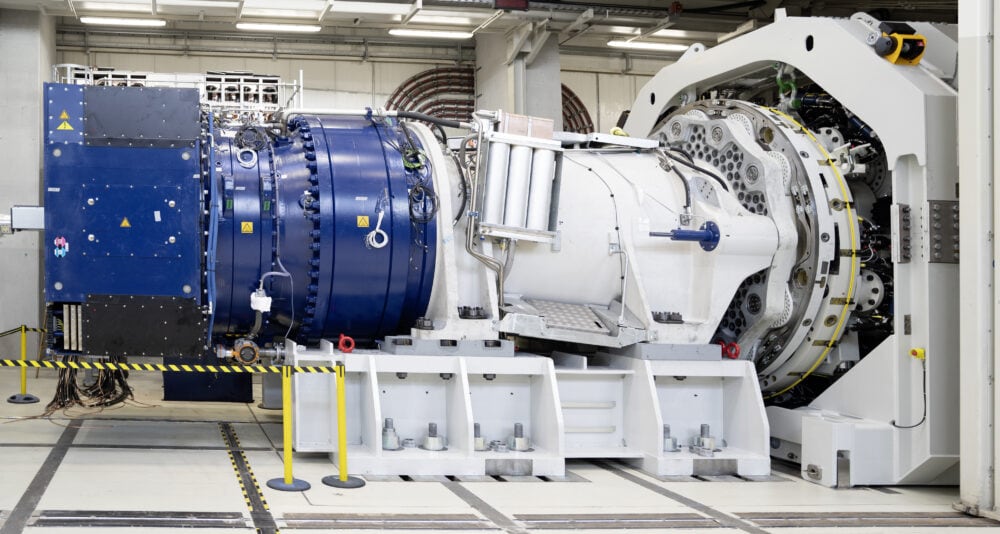

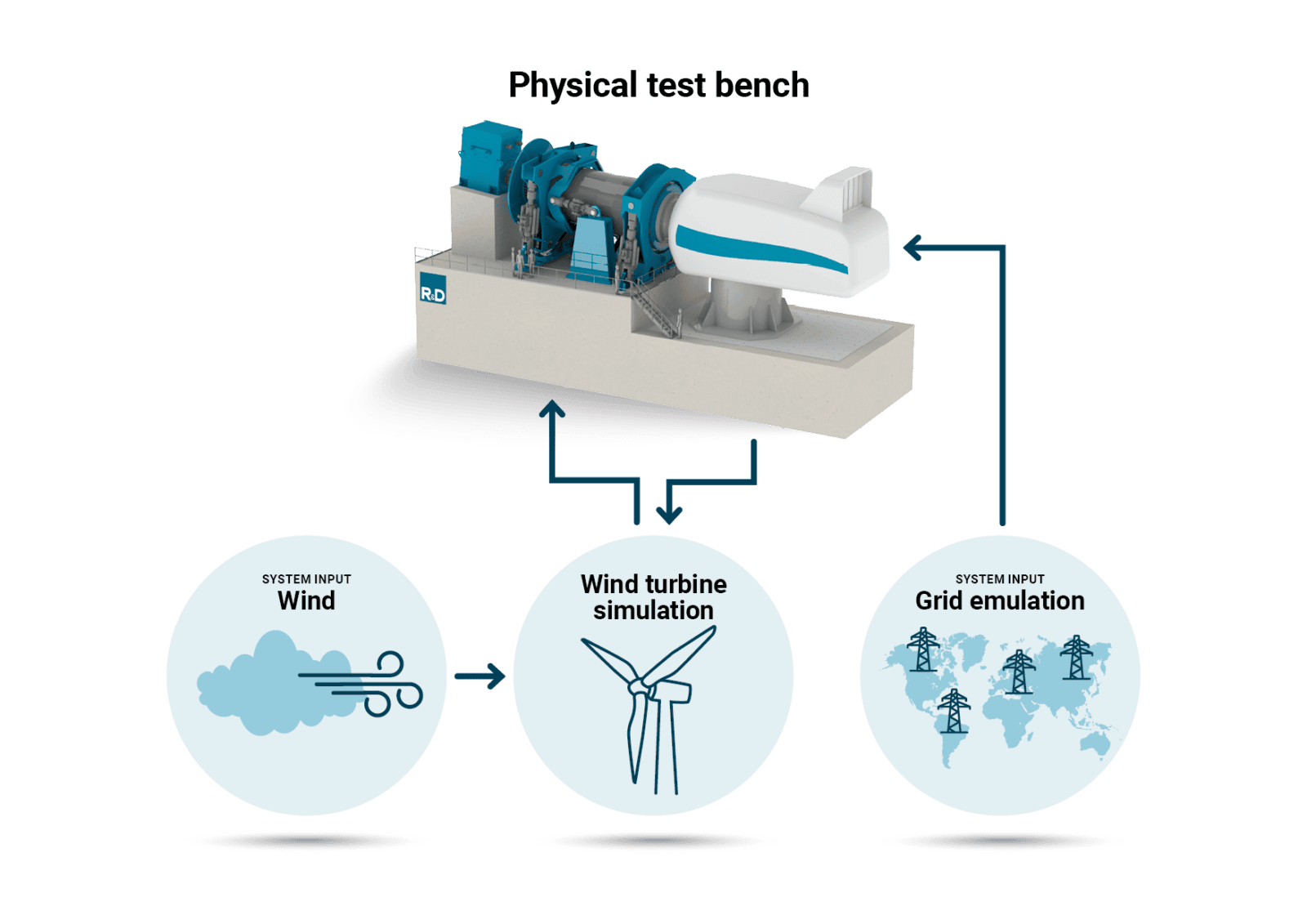

When testing wind turbines on a test bench, there will always be components or sub-systems that are not physically present, such as the rotor and the tower. To create the most realistic testing environment, Hardware-in-the-Loop (HiL) systems emulate the behavior of these missing components, such as the rotor, in real-time. This allows for highly accurate testing of the device under test and reduces the need for time-consuming prototype testing in the field.

Using HiL systems, test conditions—including wind loads, rotor size, and other environmental factors—are simulated in real-time. These simulations are based on the wind turbine manufacturer’s load models, customized to meet operational and real-world requirements. Tailored control systems integrate these models with the test bench actuators and the device under test.

On the electrical side, real-time grid simulation reproduces different grid strengths, harmonic characteristics, and failure scenarios such as voltage drops or phase jumps. Complex converter controls allow precise emulation of varying grid conditions.

Benefits of test benches with HiL systems:

- Wind Conditions: Test under any wind scenario, regardless of weather.

- Grid Variability: Simulate different grid connection points without relocating the turbine.

- Rotor Sizes: Test with multiple rotor configurations without handling physical blades.

HiL systems ensure comprehensive, efficient, and adaptable testing for wind turbines, accelerating development and reducing costs.

How can simulation models enhance your testing?

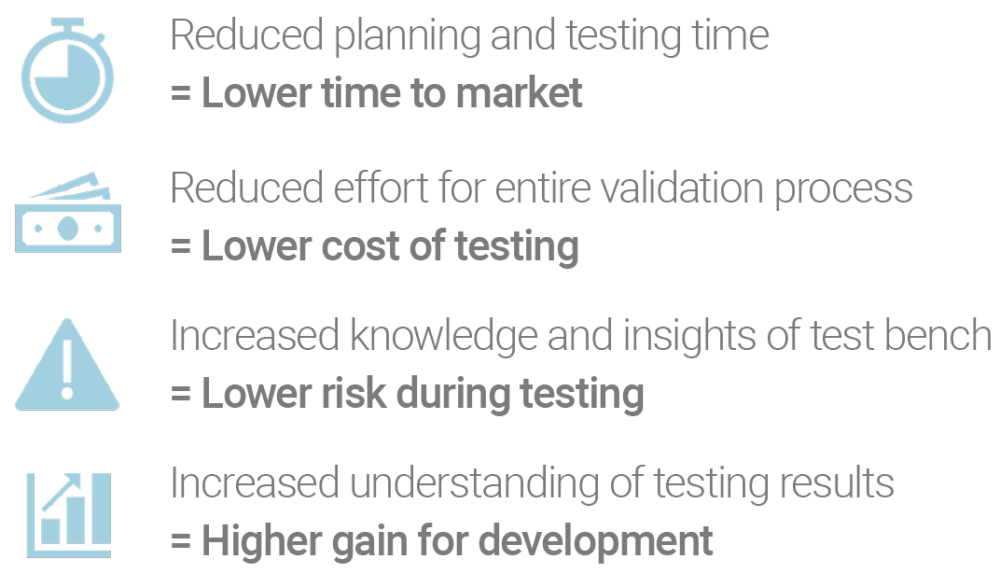

Simulation models play a vital role in modern development, not only verifying the performance of a device under test but also enhancing the testing process itself. By integrating simulation models of the device under test with the corresponding test bench model, you can unlock powerful, model-based tools to streamline and optimize your testing workflows.

These tools offer a wide range of benefits, including:

- Pre-Testing Simulation: Prepare and refine tests before using the physical test bench.

- Test Profile Optimization: Design precise and efficient test profiles tailored to your needs.

- Virtual Commissioning: Simulate the commissioning process to identify and address issues early.

- Damage Prediction: Forecast potential damage to reduce risks during testing.

- Control Optimization: Fine-tune control systems for improved performance and reliability.

- Virtual Operator Training: Provide realistic, hands-on training for operators in a risk-free environment.

While these tools do not replace physical testing, they drastically reduce the time spent on the test bench by maximizing insights and minimizing inefficiencies. This results in faster, more cost-effective testing processes with enhanced accuracy and reliability.

Our digital ambitions

We use digitalization and simulation models to improve information upfront to testing, increase transparency of the results, and shorten time-to-market for our customers.

How can we help you?