Case study

New test systems for full-scale tests at National Oilwell Varco

R&D's several years of experience was one of the most important reasons as to why NOV (Flexibles) decided to collaborate with R&D on the design and construction of two new test systems for oil pipes.

National Oilwell Varco (NOV) is one of the world’s leading companies when it comes to developing and delivering equipment for the oil and gas industry. An important aspect of the work is conducting tests of the developed oil pipes and completing product certificates, which documents the durability of the pipes under various conditions.

Throughout the entire project, we have benefitted from R&D's broad experience within the development of test systems.

Thoroughly customised solution

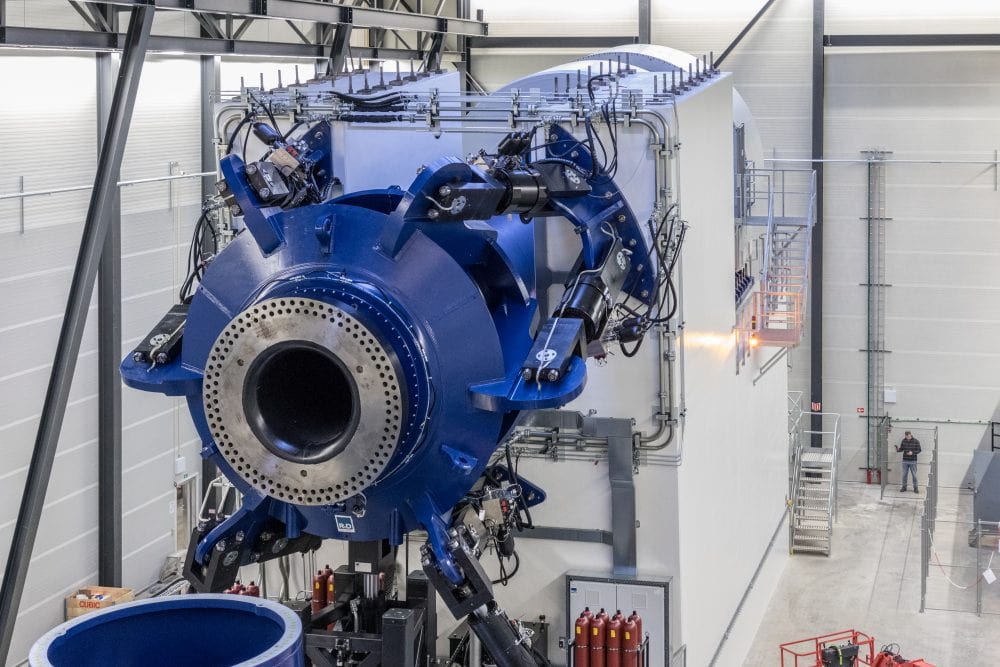

NOV’s new test systems will test the durability of the oil pipes under various conditions. They must be able to conduct full-scale tests of 17-22 metres long sections of a finished flexible oil pipe. All are tests of exhaustion, which test how great an impact the pipes can handle under various conditions, such as during a forceful wave impact. With the use of these tests, NOV can document the durability of the pipes and complete the product certificates.

The two new test systems take up much space as they have a length of 30 metres and 20 metres, respectively, and a maximum height of 6 metres. The decision to develop and construct the two new test rigs meant the construction of two new buildings, which are to contain the new equipment.

The collaboration on the development of the new test systems began several years ago. ”While preparing the project, we had many different concept suggestions and we had discussed all options before we took the final decision regarding the design and construction,” Kenth Skipper Mortensen says, Project Manager at R&D.

”For instance, when you have to simulate a pull from the ocean floor in a 2.5 kilometres long oil pipe, the test system needs to pull with a force of 600 ton, which requires a specially designed solution. Therefore we discussed the pros and cons of the different solutions with the project managers and the people responsible for the tests at NOV, and in collaboration we found the most optimal solution.”

Competent and reliable collaboration

According to NOV, the collaboration with R&D has been very valuable. ”Throughout the entire project, we have benefitted from R&D's broad experience within the development of test systems. They have been very good at considering our demands and needs, and they have proposed various solutions which have improved the final solution,” Peder Skifter Mikkelsen says, Project Manager at NOV.

The two test systems have been installed in the new buildings in Kalundborg and are ready for implementation. ”The collaboration with R&D has been very beneficial in the entire project duration,” Peder Skifter Mikkelsen says. ”We think R&D’s employees were very competent and reliable throughout the entire project and also economically beneficial. We look forward to conducting the first tests in the coming weeks.”