Design & Engineering

Improve clamping force calculations and optimized bolt design

Improve clamping force calculations and optimized bolt design

Reduce uncertainty and optimize your bolt designs

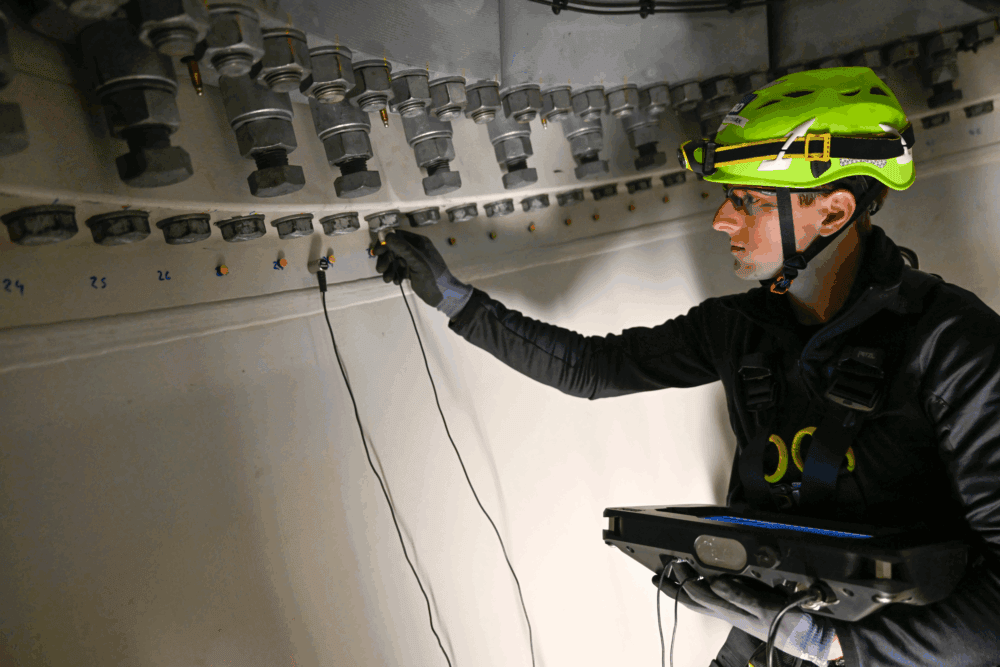

In wind turbine engineering, the design of bolted joints is crucial for structural integrity, weight, cost, and long-term performance. Engineers need confidence that their calculations will achieve the intended preload in real-world conditions.

Bolt-Check reduces uncertainty by allowing your design team to verify theoretical clamping force calculations through physical testing. This helps optimize joint configurations, minimize material usage, and specify smaller or fewer bolts where suitable — saving both weight and cost without sacrificing safety or performance.

“Before, measuring every bolt manually was a tedious task. Now, with the RFID tags and Bolt-Check’s simplified interface, we can complete inspections much faster."

- Pascal Rothstein,Technician at mh2

Read the case of how Bolt-Check improved efficiency and precision in bolt tension tasks.

Validate, execute and improve your design

With Bolt-Check, you can ensure that your design intent is carried out precisely during assembly. Installation teams are guided by your specifications and can tighten bolts to match your calculated preload values — ensuring consistency from design to field.

In addition, Bolt-Check gives you access to real-life bolt performance data across your applications. This feedback loop allows you to refine internal design guides, validate assumptions and continuously improve future designs based on real operating conditions.

From concept to installation, Bolt-Check supports a more confident, validated and data-driven approach to bolted joint design.

How Bolt-Check adds value for design and engineering:

- Reduced uncertainty in preload calculations

- Optimize designs for fewer or smaller bolts, reducing material use and weight

- Validate clamping force specifications through physical testing

- Ensure installation accuracy in the field, aligned with design intent

- Improve confidence in joint performance and structural reliability

Get in touch

Would you like to explore how Bolt-Check can improve your design process and help optimize your wind turbine structures?

Contact us for a technical discussion or demonstration.