Bolt Manufacturer

Enhance the value of your bolts

Enhance the value of your bolts

Bring your bolts to life

As a bolt manufacturer, you play a key role in ensuring the integrity and safety of bolted joints in wind turbines and other high-performance applications. With rising expectations from OEMs and installers for higher standards, better documentation and smarter solutions, staying competitive requires more than quality alone.

By integrating Bolt-Check into your production, each bolt becomes fully traceable throughout its lifecycle. A unique ID tag links the bolt to data such as type, size, material grade, E-modulus, batch number and ultrasonic measurements. Scanning the tag provides instant access to this information, helping your customers improve quality control, service planning and lifecycle management.

"Bolt-Check provides a simple yet highly effective way to verify tension. The fasteners are measured in the factory, installed, and then re-measured in the field to check for any loss of tension. It’s a straightforward process that allows customers to ensure their fasteners remain secure."

- Bolt Manufacturer using Bolt-Check

Offer verified performance and unlock new value for your customers

Bolt-Check adds more than documentation. By performing an ultrasonic reference measurement on each bolt during production, you provide a reliable baseline for future elongation and tension assessments.

This helps your customers simplify installation, reduce on-site complexity and ensure consistent measurement accuracy. It also enables a shift from fixed service intervals to predictive maintenance based on actual bolt performance.

With Bolt-Check, you deliver more than bolts — you deliver insight, reliability and long-term value.

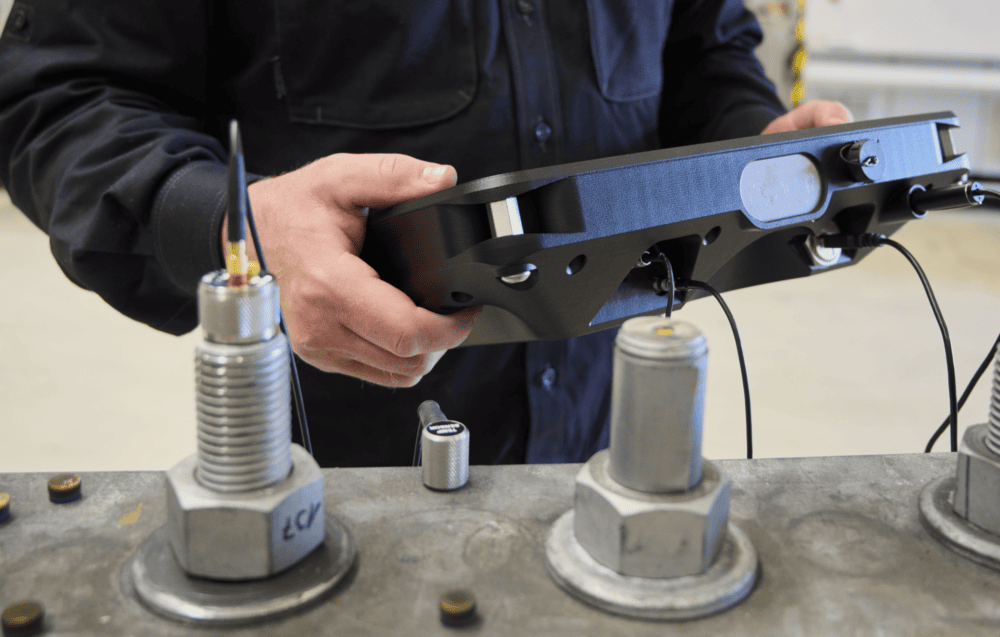

How it works

The process of implementing Bolt-Check and the unique RFID tag to bolts.

1. Prepare bolt for tag

To accommodate the RFID tag, drill a predefined small hole in the top of your bolt or stud.2. Add RFID tag to bolt

Glue the small yellow RFID tag into the drilled hole in the bolt or stud.3. Register data and pre-measurement

Register, add data such as type, size, material grade, E-modulus and batch number, and pre-measure the bolt with Bolt-Check.Let’s talk bolt quality

Want to learn more about Bolt-Check and meet customer demands for documentation and traceability?

Contact us for a technical discussion or demonstration.