Case study

Steel components to large wind power test centre

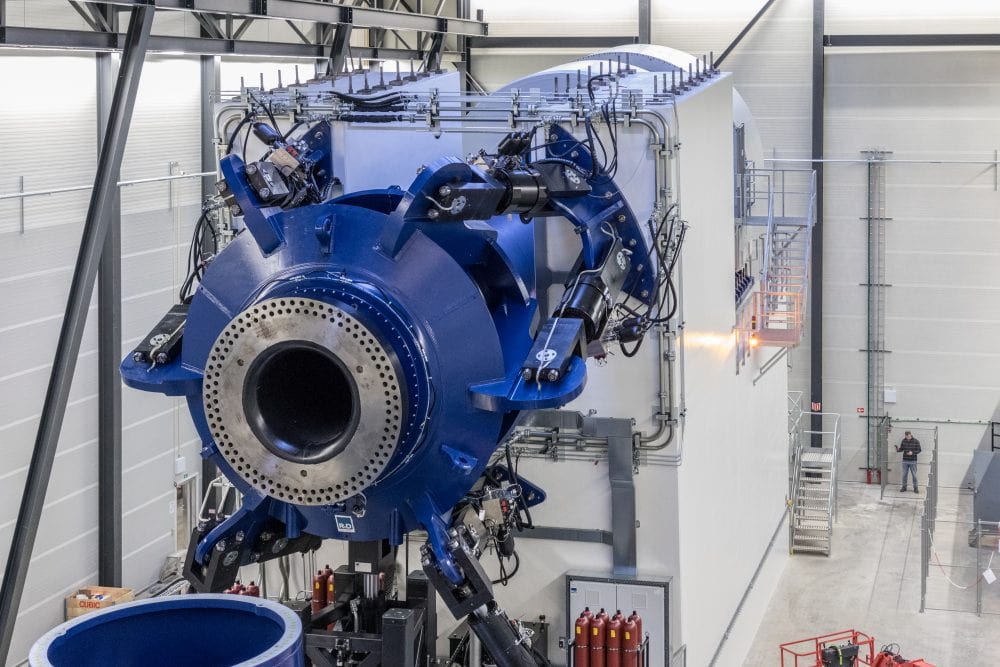

In relation to the installation of a new test centre at DTU, R&D Steel has been asked to deliver multiple steel components. The test centre is a large wind tunnel dedicated to wind power.

The order has been secured through Dansk Halbyggeri, who is the general contractor on the project. It is the first time R&D Steel and Dansk Halbyggeri collaborate on a project but hopefully not the last.

R&D Steel is in charge of delivering steel components which will be used to lift wind turbine blades during testing. R&D Steel has initially delivered a set of embedment models which have been drawn and designed in-house by engineers from R&D. Afterwards, the models have been manufactured by R&D Steel. The embedment models will ease the mounting of processed flanges. These flanges are also manufactured by R&D Steel.

The largest embedment model is 3.9 metres long, has a diameter of 3 metres and weighs 2.4 ton. The smallest model is 1.4 metres long, has a diameter of 1.3 metres and weighs almost 200 kg.

For more information on the test centre and the new wind tunnel, please follow this link.