Case study

Construction and assembly of two traver systems for National Oilwell Varco

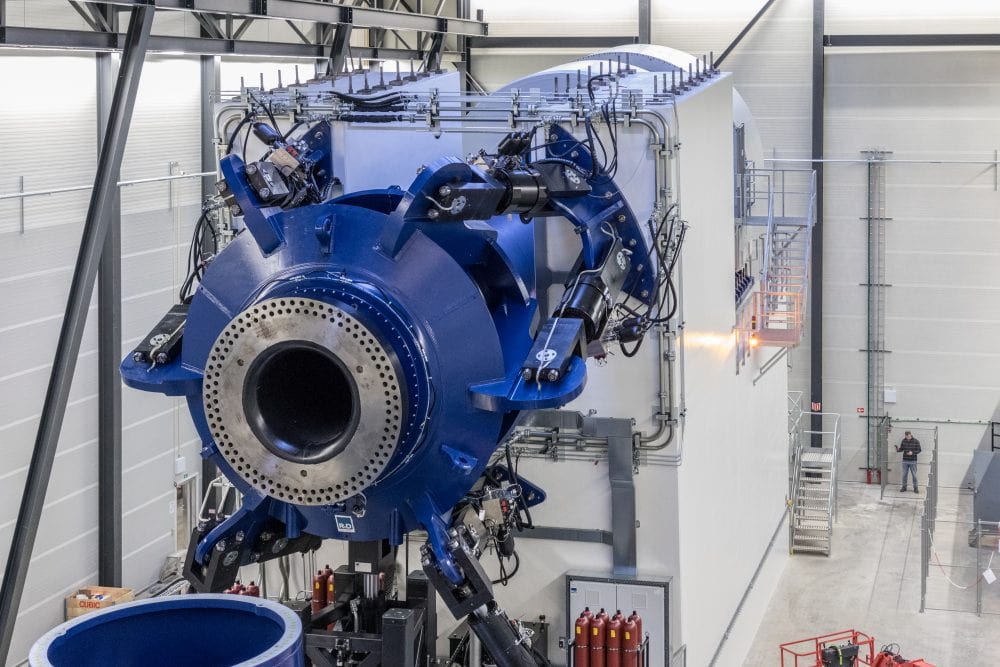

The service department at R&D has been in charge of assembling, adjusting and installing two 6-ton heavy and 18 metres long traver systems for National Oilwell Varco.

The work has been conducted in collaboration with the colleagues at R&D Test Systems, who have been responsible for the construction. The two traver systems for NOV will be used for testing the durability of oil pipes - for instance how great an impact from waves the pipes can handle before they leak or break.

For several years, the collaboration with project manager Kenth Skipper Mortensen and many of the engineers from the test department at R&D has been very beneficial.

Customer satisfaction

”In this case construction, assembly, adjustment and installation were all closely related, which is why we saw several advantages of assembling everything in our own facilities,” Jacob Olsen says, Service Manager at R&D. ”We have the right competences and therefore we offered to be fully responsible for the assembly – also with respect to the involved suppliers.”

Project Manager at NOV, Peder Skifter Mikkelsen, immediately welcomed R&D's proposal to be responsible for the assembly. ”For several years, the collaboration with Project Manager, Kenth Skipper Mortensen, and many of the engineers from the test department at R&D has been very beneficial. When Kenth and the Service Manager Jacob Olsen presented the idea, it made perfect sense to pre-assemble the traver systems at R&D and install them at our facility afterwards.

If any problems were to arise, they would be able to easily contact the engineers who had constructed the system and solve the problems together. Afterwards, R&D arranged the transportation from Aarhus to our location in Kalundborg as well, and we were very satisfied with the entire process.”

Experienced team

”Our experience in constructing, assembling and installing the traver systems are important know-how in the subsequent servicing of the construction,” Jacob Olsen says. ”We are not used to this type of assembly projects in our department, but when we saw the close correlation between the construction, assembly and installation we realised that the customer would receive the best solution if we were responsible for the entire project. At the same time, we will gain valuable experience, which will be useful for other construction projects and the subsequent servicing.”