Test Systems

The critical role of testing wind turbines

The critical role of testing wind turbines

The global push for renewable energy has propelled wind power to the forefront of sustainable electricity generation. Wind turbines are growing in size, complexity, and efficiency, making rigorous testing more critical than ever. With the increasing scale of components such as rotor blades, gearboxes, and bearings, the industry faces new engineering challenges that demand cutting-edge test systems to validate performance, reliability, and safety.

Why testing matters for wind turbine reliability

Wind turbines operate under extreme conditions—strong winds, temperature variations, and varying loads—over lifetimes exceeding 20 years. Without thorough testing, the risk of unexpected failures rises, leading to costly downtime and maintenance. Studies indicate that unplanned maintenance accounts for up to 60% of operational costs in offshore wind farms. Furthermore, several OEMs have in recent years reported serial defects and losses exceeding hundreds of millions of euros due to faulty components, highlighting the financial impact of insufficient validation.

Michael Buus Nielsen, General Manager at R&D Test Systems, explains: "Unlike industries such as automotive and aerospace, where testing standards are well-established, wind energy is still working towards standardized large-scale testing. In aviation, every aircraft component undergoes extensive validation to prevent failures. Similarly, automotive manufacturers rely on crash tests and durability simulations to ensure safety. However, wind turbines have grown so quickly in size and complexity that testing has struggled to keep up, resulting in more failures in the field. To ensure long-term reliability, we must apply the same rigorous testing principles used in these industries."

To mitigate risks, comprehensive testing focuses on structural integrity, drivetrain reliability, power electronics efficiency, and extreme condition simulations. By identifying potential failures early, manufacturers can reduce maintenance costs and ensure the long-term performance of wind turbines. Additionally, testing is a critical competitive factor—companies that validate their technology early can bring reliable turbines to market faster, strengthening their position in an increasingly demanding industry.

R&D Test Systems: The trusted partner for wind turbine testing

As a leading provider of specialized test systems, R&D Test Systems delivers tailor-made solutions for wind turbine manufacturers, component suppliers, and certification bodies. We offer end-to-end expertise, from concept development to commissioning, ensuring that every test solution is precisely tailored to specific needs. Our state-of-the-art test benches simulate real-world operating conditions, reducing the gap between laboratory and field performance. With decades of experience in wind energy testing, we have supported industry leaders in achieving higher reliability and lower operational risks. Additionally, we continuously integrate the latest technological advancements to meet evolving industry standards, ensuring our test solutions remain future-proof.

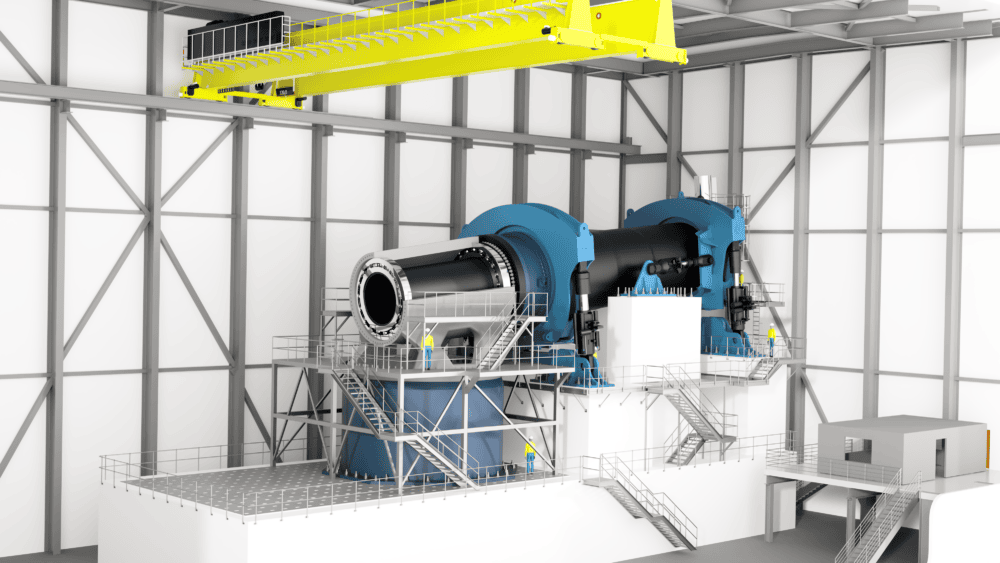

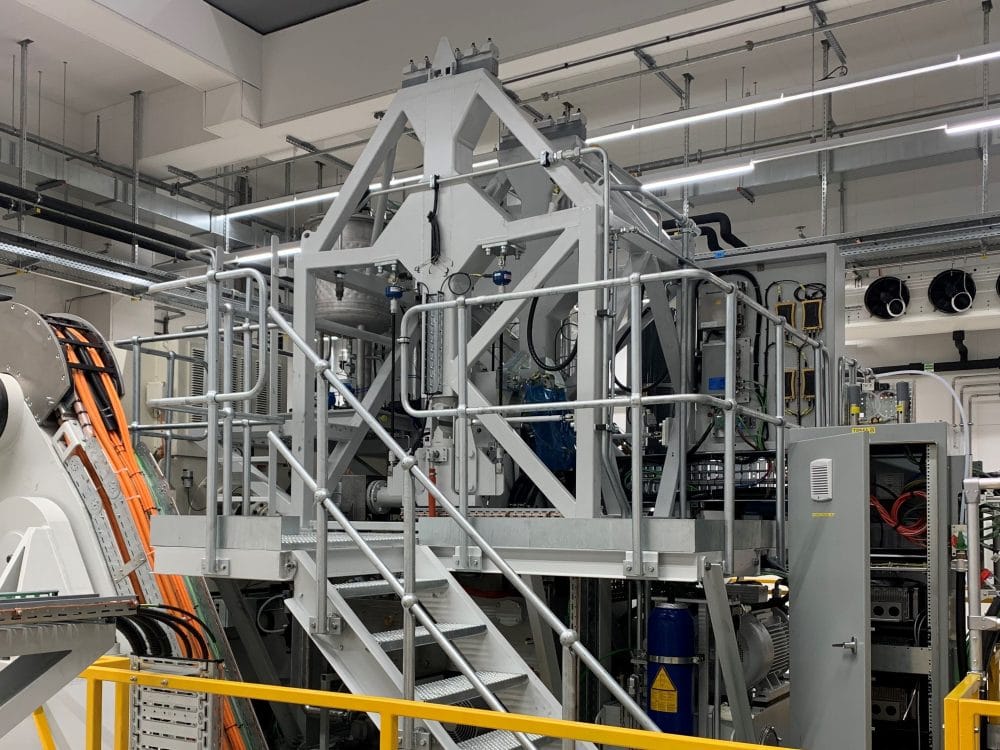

R&D Test Systems has developed and delivered some of the most advanced test benches in the industry, including the 30MW powertrain and gearbox test bench for ZF Wind Power and the 25 MW Test Facility for design verification and lifetime validation at LORC. These facilities play a crucial role in validating the next generation of offshore wind

turbines. These cutting-edge facilities provide comprehensive validation under real-world conditions, ensuring turbine components meet the highest standards of reliability and performance.

Michael Buus Nielsen emphasizes the importance of testing in advancing wind energy: "Reliable and efficient wind turbines are the backbone of a sustainable energy future. At R&D Test Systems, we provide cutting-edge test solutions that help manufacturers push technological boundaries while ensuring long-term performance and safety. Our expertise ensures that every component meets the highest industry standards before deployment."

In a rapidly evolving wind energy landscape, testing is the key to achieving long-term turbine reliability and performance. With R&D Test Systems as your trusted partner, you gain access to world-class expertise and test solutions designed to meet the demands of tomorrow’s wind power industry.

Unlike industries such as automotive and aerospace, where testing standards are well-established, wind energy is still working towards standardized large-scale testing.

Want to know more?