Test Systems

Bearing test rig for Rolls-Royce UltraFan

Bearing test rig for Rolls-Royce UltraFan

R&D Test Systems’ high-performance test rig for bearings, a key component of a new Power Gearbox, has been installed at the Rolls-Royce facility in Germany. This gearbox is a key innovation in Rolls-Royce’s new UltraFan® jet engine demonstrator, helping to deliver new levels of efficiency and environmental sustainability

Danish company R&D Test Systems has developed a custom-designed test rig for bearings, a component critical to the function of the new Power Gearbox in Rolls-Royce’s engine demonstrator programme, UltraFan. A key element of Rolls-Royce’s sustainability strategy, UltraFan offers a fuel burn improvement of 25% compared with the first generation of Trent engine. It is also fully capable of running on 100% Sustainable Aviation Fuel.

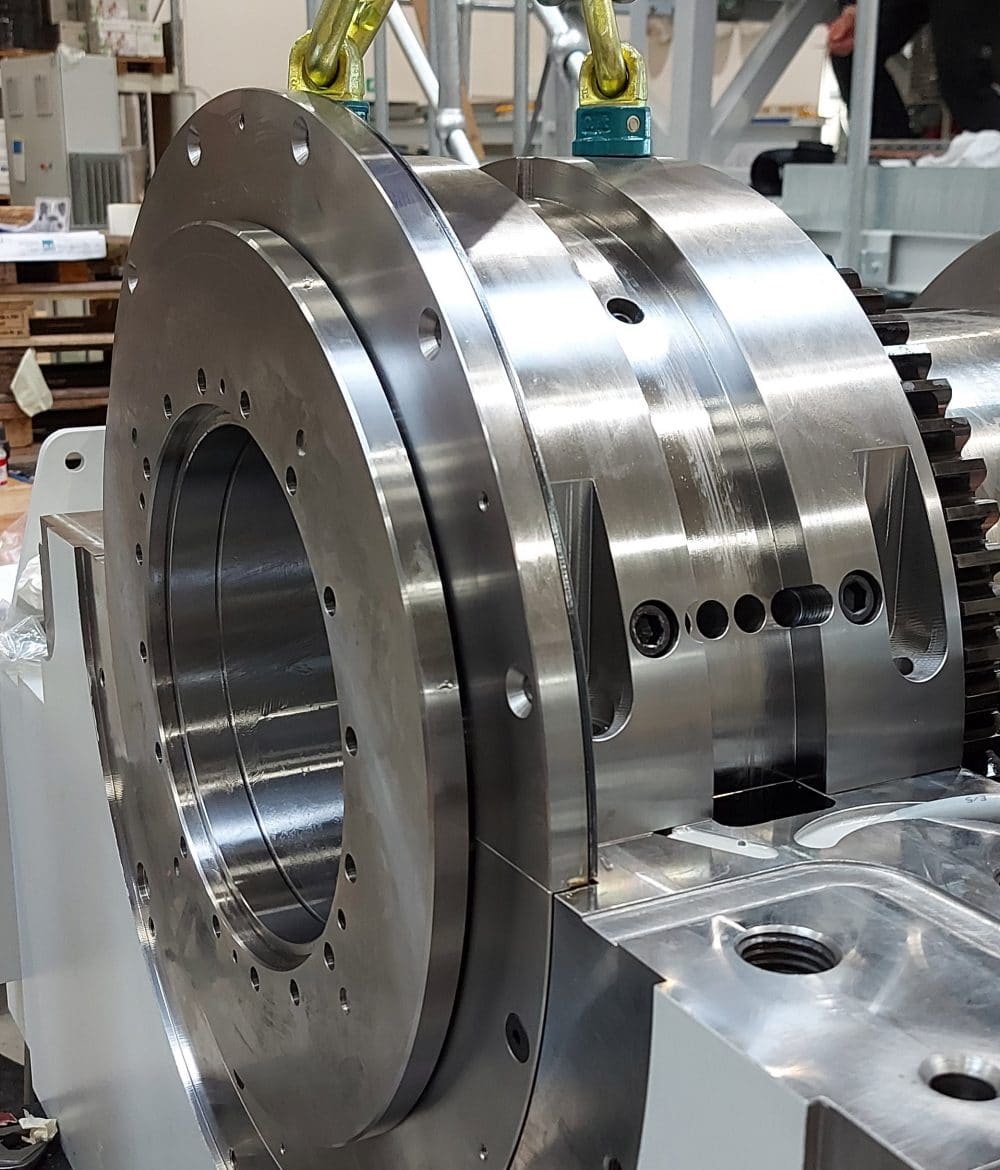

A key innovation of the UltraFan design is the introduction of the high-performance Power Gearbox situated between the fan and compressor. The bearings that are being tested on the R&D Test Systems test rig are a pivotal component in the new UltraFan Power Gearbox, which is rated at 50 MW – the equivalent of 500 family cars.

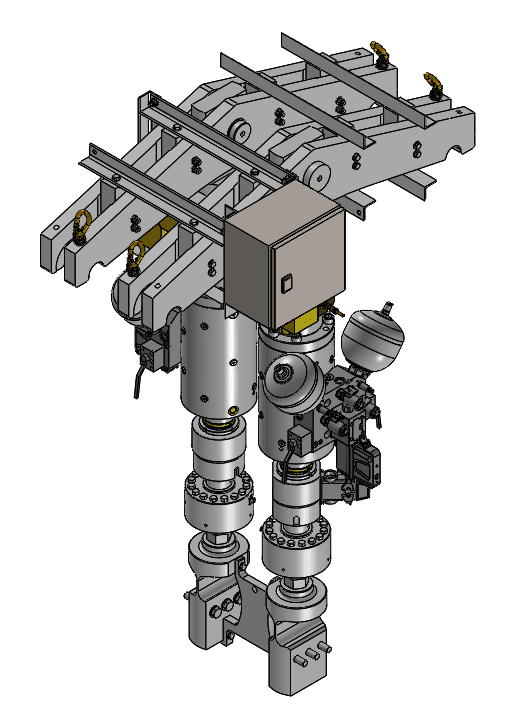

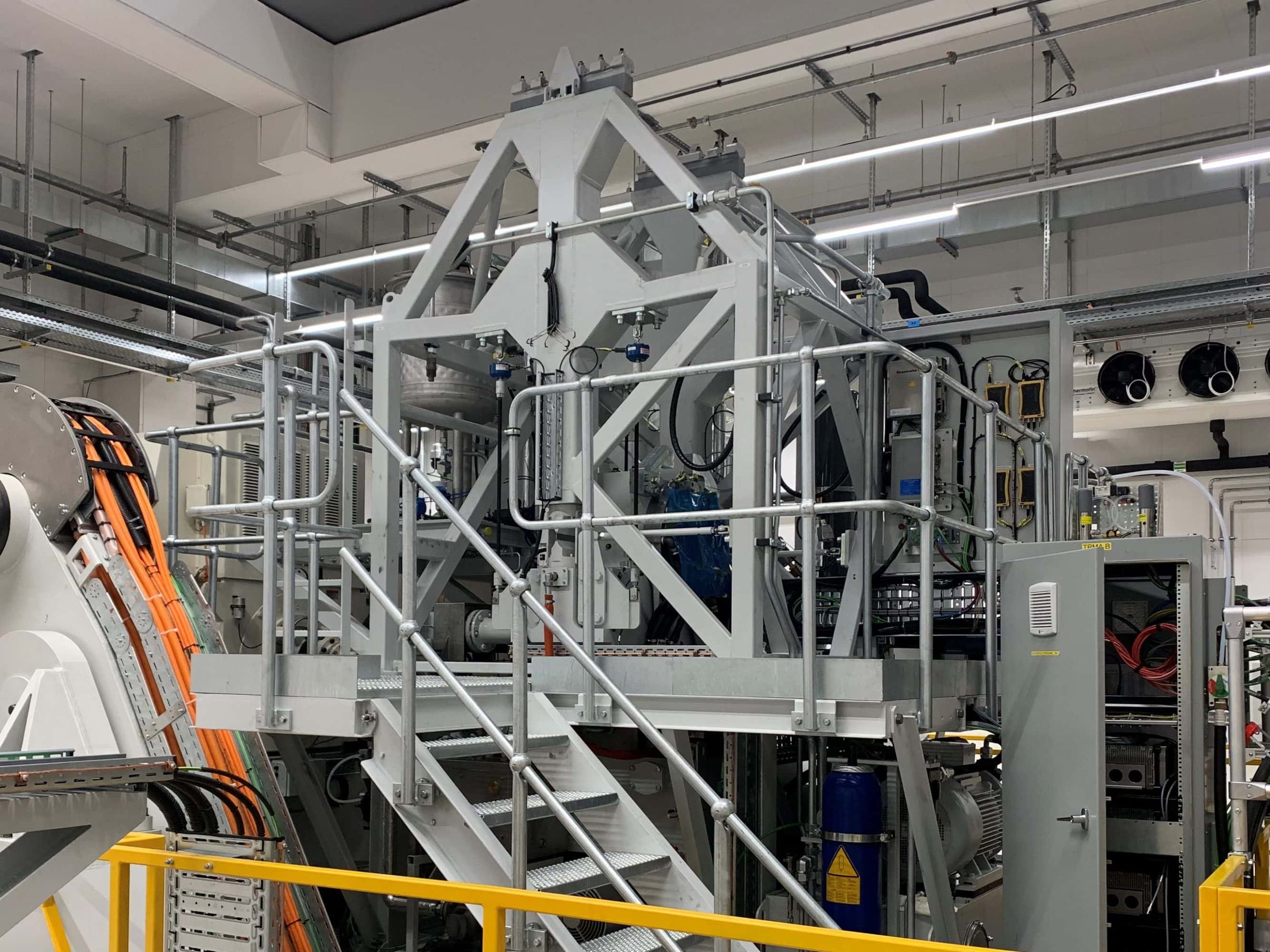

Capable of simulating extreme operating and environmental conditions, the test rig, which was recently delivered to the engine manufacturer’s facility in Dahlewitz, Germany, offers fast mounting of the components to be tested, multiple high-precision measurements, and rapid assembly of the test rig thanks to its compact, flexible and modular design.

It is great to see the test rig developed by R&D’s engineers up and running at our facility at Dahlewitz

High-precision test rig

The high-precision test rig allows the measurement of 350 different data points, most of them via sensors observing a particular aspect of the bearings in the greatest possible detail. In addition to proximity, load, tilt, and temperature sensors, the test rig also incorporates a specially designed hydraulic system to apply precise load.

“R&D’s multidisciplinary team of mechanical and software engineers is proud to support Rolls-Royce’s tests on a major component of the completely new Power Gearbox within UltraFan,” said Asger Krogstrup, project manager at R&D Test Systems.

“It has been both an exciting and challenging project taking us to the limits of what is technologically possible,” said Krogstrup. “We have had close cooperation with Rolls-Royce from start to finish to ensure the best integration of the test rig into its development work in Germany,” he added.

The test rig – which is R&D Test Systems’ latest project for the aerospace sector – was designed to be easy and quick to disassemble, optimised for changeover time for test campaigns, sometimes as short as one to two days, and supports failure-safe installation of a new component for test.

“It is great to see the test rig developed by R&D’s engineers up and running at our facility at Dahlewitz,” commented Holger Klinger, Sub-System Executive at Rolls-Royce. “We have worked on this joint project for more than two years to develop this proving ground for the bearings that will be used in the new Power Gearbox for the UltraFan.”

Custom-designed solutions

The bearing test rig will be managing drivetrain speeds of above 5,000 rpm and torque levels above 1,500 Nm. The cross-functional R&D Test Systems team also custom-designed lubrication units to use contaminants for environmental testing and a test management system, capable of event monitoring and automated fault handling to reduce operator involvement, saving time and increasing both speed and accuracy of the testing.

The new bearing test rig will allow Rolls-Royce to test the performance of this key component under both normal and extreme operating conditions. At the same time, an extensive amount of high-precision data will be collected for subsequent analysis and documentation. This will enable a faster and more iterative development process, as well as continuous testing at several stages during the build phase, making the test rig an important element in the development of these bearings.