Insights

R&D builds demonstrator for new energy-efficient testing

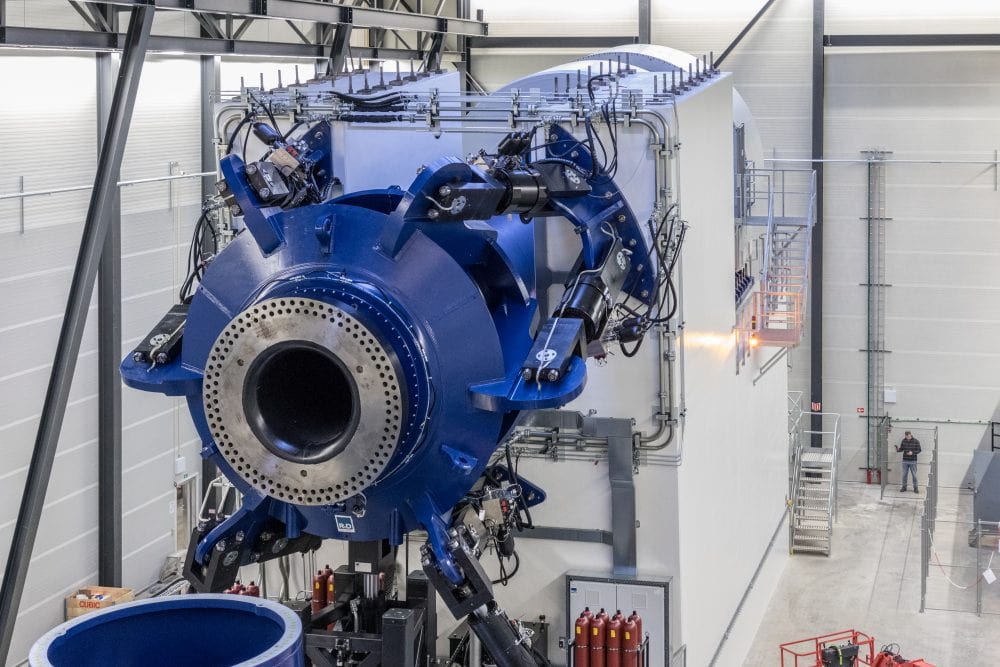

For several years, R&D has been collaborating closely with Aalborg University on developing a more realistic and energy-efficient test method for wind turbines. Right now, a demonstrator of the new test bench is being built in R&D's assembly hall.

It requires considerable amounts of energy to test 25 years of wind load on an 8MW offshore wind turbine. The 3 year long development in which R&D collaborates closely with Aalborg University has the overall goal of developing a test bench which conducts the tests as realistically as possible, keeps the time of the tests to a minimum and consumes less energy than the test systems available today.

”At this moment, we are building a demonstrator of our wind load simulator test bench for accelerated life cycle tests of wind turbines. The demonstrator will be capable of conducting a lifetime test of a 350 kW wind turbine, and it is an important part of the research and development project, as it is an opportunity to conduct a realistic test,” Rico Hjerm Hansen says, civil engineer at R&D.

”The completed test bench will be three to four times bigger than the demonstrator in order to be able to test the largest wind turbines today.”

Assembly at R&D

The construction of the demonstrator is currently under way in the assembly hall at R&D, where R&D's employees will assemble, adjust and finally install it at Aalborg University. The location will allow close collaboration between the university and R&D in the subsequent running-in and conduction of tests in which the developed software solutions are tested and verified.

The project is supported by EUDP (the Energy Technology Development and Demonstration program) which is an initiative by the Danish Energy Agency to render Denmark independent of fossil fuels. R&D, which for several years has been one of the world’s leading companies within the development of test systems for wind turbines, is collaborating closely with internationally prominent authorities from Aalborg University’s Department of Energy Technology. The united competences create a very strong synergy.

Great interest in more realistic tests

"We are currently working on several specific customer projects with the aid of the new test principles,” Peter Ulrikkeholm says, Business Unit Director at R&D Test Systems. ”The more realistic test of load conditions increases the possibility of immediately finding the flaws and errors which can be problematic and expensive later in the process. The project is very interesting both in operational, economical and environmental aspects for our current customers as well as our potential customers.”