Installation

Secure reliable and data-driven bolt installation

Secure reliable and data-driven bolt installation

Straightforward bolt installation

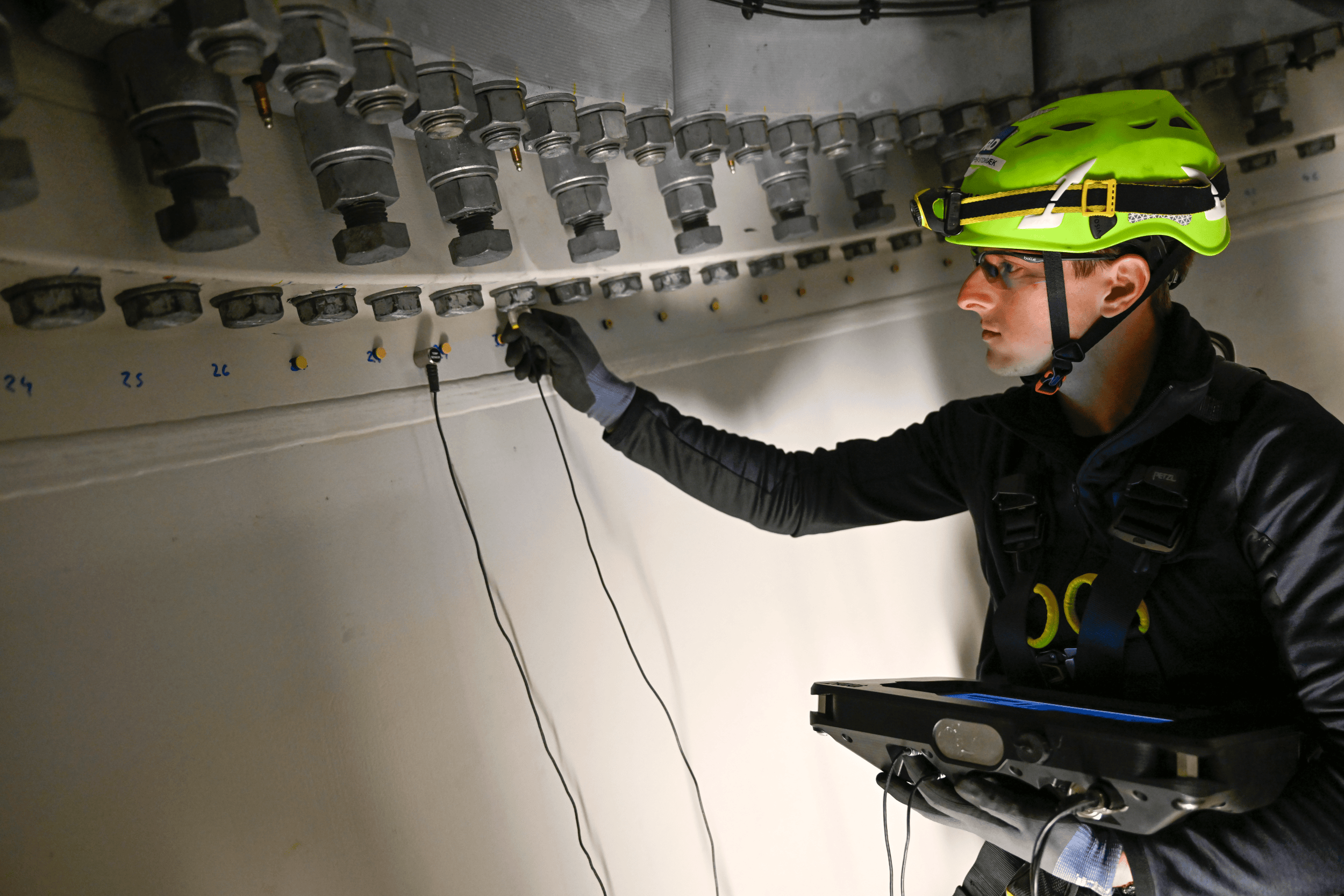

During wind turbine installation, precision and documentation are crucial. Every bolted connection must meet strict specifications to ensure long-term performance and safety, and the tightening process must be fully traceable.

With Bolt-Check, installation teams can carry out data-driven bolt tightening with high precision, ensuring each connection is completed correctly and reliably.

Manual data entry is eliminated, as all tightening data is automatically captured and uploaded to the cloud. This reduces the risk of human error and ensures that critical documentation is never misplaced. The process streamlines workflows and supports full compliance with OEM and project requirements.

In short, Bolt-Check simplifies bolt installation while improving accuracy, traceability and accountability.

How Bolt-Check adds value for installation teams:

-

Enables accurate, specification-based bolt tightening

-

Removes the need for manual data entry

-

Automatically stores documentation in the cloud

-

Minimizes risk of human error during installation

-

Ensures full traceability and project compliance

"Any large bolts requiring precise tensioning should be checked with ultrasonic measurement. It increases bolt lifespan and ensures consistent, correct tensioning.”

- Mr. Eyðfinnur Lenvig, Technician at J&K Petersen Contractors

Read the case of how Bolt-Check reduced maintenance costs by 75%

Get in touch

Would you like to learn how Bolt-Check can improve the quality and efficiency of your installations?

Contact us for a technical discussion or demonstration.